Signs of Micro-Wear: Knowing When to Renew Your Tweezers

The Invisible Degradation of Professional Precision

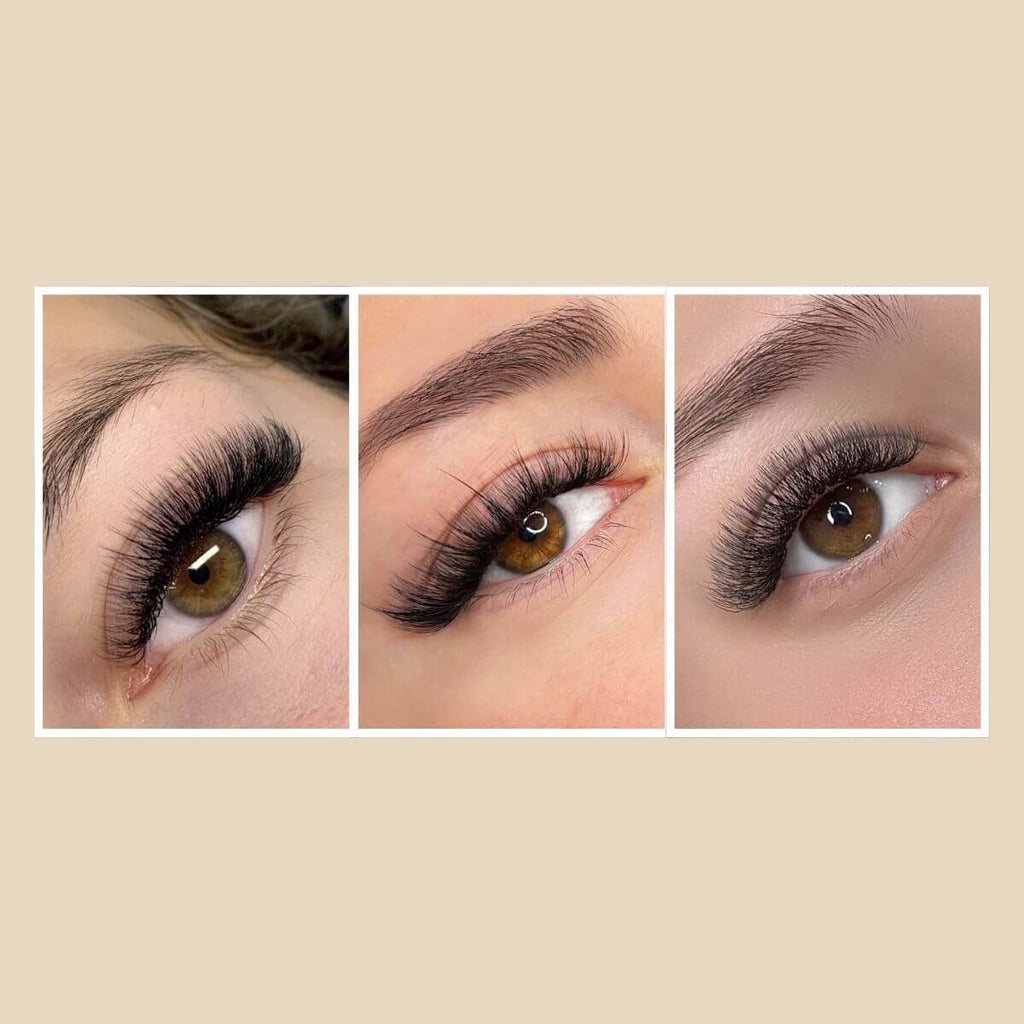

In the high-stakes environment of professional lash artistry, the difference between a flawless mega-volume set and a retention failure often comes down to a fraction of a millimeter. While most salon owners focus on adhesive chemistry and lash fiber quality, the most critical link in the service chain is frequently the most overlooked: the precision tweezer.

For an elite lash artist, tweezers are not merely tools; they are an extension of the nervous system. However, even the highest-grade surgical steel is subject to the laws of physics. Micro-wear—the gradual, often invisible degradation of the tool’s "sweet spot" and tension—can silently erode service quality long before a tool appears "broken."

This guide explores the technical indicators of tool fatigue, the material science of tip abrasion, and the operational protocols required to maintain a gold-standard service. By understanding the lifecycle of your precision instruments, you can protect your client's ocular health, reduce hand fatigue, and ensure the long-term profitability of your salon.

The Tactile Feedback Loop: Identifying "Mushiness"

Experienced professionals recognize that the first sign of tweezer wear is not visual, but tactile. It manifests as a subtle "mushiness" in the spring action. This sensation occurs when the metal begins to lose its elastic memory—a phenomenon known as metal fatigue. When the tension is no longer crisp, the artist must apply more manual pressure to achieve the same grip strength.

This over-compensation is the primary driver of carpal tunnel syndrome and general hand fatigue in high-volume salons. When working with ultra-fine fibers like 0.07MM Cashmere Premium Mega Volume Eyelash Extensions, which require a delicate touch to avoid crushing the base, a loss of spring tension makes consistent fan creation nearly impossible.

Logic Summary: The Over-Compensation Cycle

- Observation: Tactile "mushiness" in the tweezer pivot point.

- Mechanism: Metal fatigue reduces the tool's ability to return to its original "open" state with consistent force.

- Result: Artist increases grip pressure by an estimated 15–20% (based on ergonomic shop heuristics) to ensure the fan doesn't slip.

- Outcome: Accelerated hand fatigue and increased risk of "popping" fans during placement.

Micro-Wear and Material Science: Why Matte Lashes Abrade Tips Faster

It is a common misconception that stainless steel is impervious to the soft fibers of synthetic lashes. In reality, the texture of the lash extension plays a significant role in tool longevity.

Recent industry observations suggest that matte-finish and "cashmere" lashes, while aesthetically superior for deep black sets, are more abrasive than traditional glossy PBT (Polybutylene Terephthalate) fibers. The microscopic "tooth" of a matte finish acts like an ultra-fine sanding block. Over hundreds of sets, this texture creates micron-level burrs on the interior surface of the tweezer tips.

For those using 0.07MM Easy Fanning Eyelash Extensions, the stakes are even higher. Because these lashes feature a unique sticky base to assist in fan creation, any imperfection on the tweezer tip can cause the adhesive to snag, resulting in a twisted fan or a snapped fiber. If you notice that your lashes are starting to "roll" or "twist" during the pickup phase, it is likely a sign that the tip alignment has been compromised by microscopic abrasion.

The Health Correlation: Tool Integrity as a Safety Barrier

Maintaining pristine tools is not just about aesthetics; it is a fundamental requirement for client safety. According to the American Academy of Ophthalmology (AAO), eyelash extensions carry inherent risks of infection and trauma. When tweezers lose their precision, the artist is more likely to engage in "mechanical rubbing" or multiple attempts at isolation, which increases the risk of corneal abrasion.

Furthermore, the Centers for Disease Control and Prevention (CDC) emphasizes that proper sanitation is the only way to prevent the spread of conjunctivitis (pink eye). Old tweezers with micro-pitting on the surface are significantly harder to sterilize. Bacteria and adhesive residue can hide in these microscopic craters, creating a reservoir for pathogens.

Ocular Health Risks Linked to Tool Failure

- Blepharitis: Eyelid inflammation often exacerbated by bacteria buildup. As noted by the Mayo Clinic, hygiene is paramount. Tools that cannot be cleaned to a "factory-new" state due to surface wear should be retired.

- Chemical Burns: Loss of grip precision can lead to extensions falling into the eye during application, potentially carrying wet adhesive to the ocular surface.

- Microbiome Alteration: A 2024 study published in PMC suggests that long-term extension wear alters the ocular surface microbiome. Using worn, contaminated tools introduces foreign bacteria that can disrupt this delicate balance.

Operational ROI: The 300-Set Renewal Heuristic

Salon owners often struggle to justify the cost of frequent tool replacement. However, when viewed through the lens of operational efficiency, a regular renewal cycle is a high-yield investment.

Based on professional usage patterns, we have developed a lifecycle model for precision tweezers. While high-quality steel can last longer, the "peak performance" window is shorter than most realize.

Tweezer Lifecycle Modeling (Professional Grade)

| Parameter | Standard Usage | High-Volume / Mega Volume | Rationale |

|---|---|---|---|

| Service Sets | 300 - 400 | 150 - 200 | Mega volume requires tighter tolerances. |

| Lash Diameter | 0.15mm - 0.10mm | 0.07mm - 0.03mm | Finer lashes demand higher tip alignment. |

| Adhesive Type | Polymer-based | Cyanoacrylate-heavy | Cyanoacrylate crystallization is more abrasive. |

| Cleaning Frequency | Daily | After every set | Solvent exposure affects metal temper over time. |

| Replacement Cycle | 6 - 8 Months | 3 - 4 Months | Prevents "mushiness" and hand fatigue. |

Method & Assumptions: This model assumes the use of 304 or 316-grade stainless steel tweezers and daily immersion in professional-grade disinfectant. Boundary conditions: The lifecycle halves if tools are dropped or if used with high-tack "easy fan" strips without regular solvent cleaning.

For salons utilizing 10D Handmade Loose Premade Fans Pointy Base(500 Fans) or 14D Handmade Loose Premade Fans Pointy Base(500 Fans), the wear on tweezers is slightly different. Since the fans are already formed, the primary stress is on the "pickup" and "placement" phases. Even so, a blunt tip can damage the delicate heat-bonded base of these fans, negating the time-saving benefits of promade sets.

Maintenance SOPs for Extended Lifecycle

While every tool has a finite lifespan, specific professional habits can extend the "peak performance" window and ensure the safety of the service.

1. The Rotation Strategy

Professionals who utilize a rotation of 2-3 identical tweezer pairs report significantly longer lifespans for their tools. This is not just about hygiene; it allows "metal fatigue to reset." By alternating tools, you reduce the continuous mechanical stress on a single pivot point, allowing the metal to maintain its elastic tension for more total sets.

2. Daily Solvent Cleaning

Cyanoacrylate-based glues are notoriously difficult to remove once they crystallize. These crystals are harder than the lash fibers and act as an abrasive against the tweezer tips. A daily solvent soak (using a dedicated adhesive remover) is non-negotiable. This prevents the "buildup-scrape-damage" cycle that ruins most tweezers within the first month of use.

3. The "Drop Test" vs. The "Light Test"

If you drop your tweezers, they should be retired immediately or relegated to non-precision tasks (like removing lash strips from the tray). Even if the damage isn't visible, the alignment is likely shifted. For daily checks, hold your tweezers up to a bright light source and close them gently. If you see any light leaking through the tips, the "sweet spot" has shifted, and the tool is no longer suitable for volume work.

Business Impact: Why Quality Tools Protect Your Reputation

In an increasingly regulated market, compliance is a competitive advantage. The Health Canada 2023-2024 Report highlights the growing scrutiny on the lash industry, particularly regarding chemical safety and application standards.

Using worn-out tools leads to poor retention, which is the #1 cause of client churn. When a client loses their lashes prematurely, they rarely blame the tool; they blame the artist's skill or the product's quality. By establishing a 300-set renewal heuristic, you ensure that your technical execution remains flawless, protecting your brand reputation and justifying premium service pricing.

Key Takeaways for the Professional

- Listen to your hands: Tactile "mushiness" is the first warning sign of metal fatigue.

- Audit your materials: Matte and cashmere lashes accelerate tip wear; adjust your renewal cycle accordingly.

- Prioritize safety: Micro-pitted tools are a sanitation risk (CDC) and increase the chance of mechanical eye trauma (AAO).

- Invest in rotation: Using 2-3 identical pairs extends the lifespan of each tool and reduces hand strain.

- Know when to let go: A precision tool is an investment in your career longevity. Do not wait for a tool to fail completely before replacing it.

YMYL Disclaimer: This article is for informational purposes only and does not constitute professional medical, legal, or financial advice. Eyelash extension procedures involve risks to ocular health. Always consult with a qualified medical professional regarding eye conditions and ensure compliance with local health and safety regulations.

References

- American Academy of Ophthalmology (AAO) - Eyelash Extension Safety

- Centers for Disease Control and Prevention (CDC) - Conjunctivitis Prevention

- Mayo Clinic - Blepharitis Symptoms and Causes

- Health Canada - Cosmetic Regulations Enforcement Summary

- PMC - Ocular Surface Microbiome and Eyelash Extensions (2024)