Troubleshooting Fiber Slippage in 0.03mm Mega Volume Fans

The Technical Challenge of 0.03mm Mega Volume

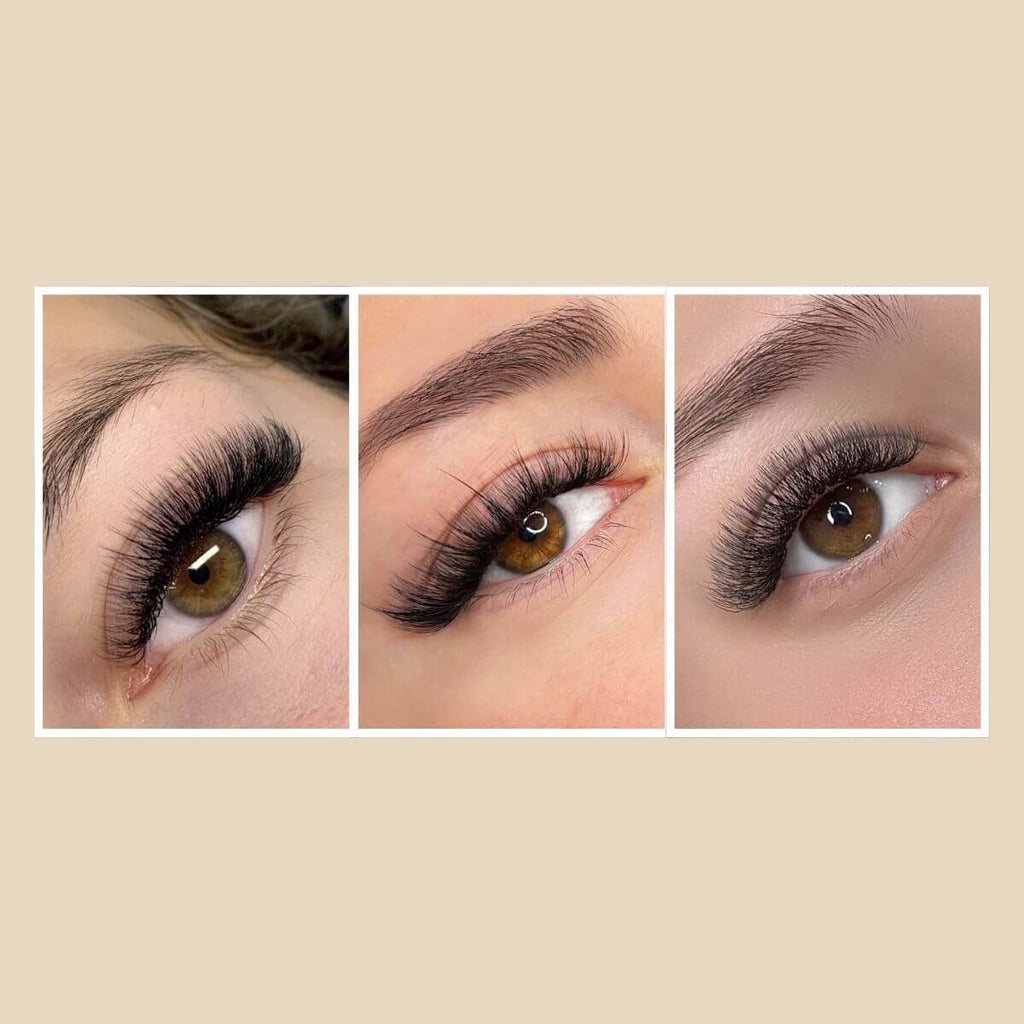

In the pursuit of the "blackout" lash look, the 0.03mm fiber represents the pinnacle of professional artistry. These ultra-fine filaments allow us to create high-density fans—often 10D to 20D—without exceeding the weight threshold of the natural lash. However, as many experienced technicians have discovered, working with 0.03mm fibers introduces a unique set of frustrations, chief among them being fiber slippage.

When a fan "slips," the individual fibers lose their alignment at the base, leading to "boxy" bases, uneven fan symmetry, or total fan collapse during placement. This isn't merely an aesthetic issue; it is a technical failure that impacts service speed and long-term retention. In our experience troubleshooting with thousands of lash artists, we’ve observed that slippage is rarely the result of a single factor. Instead, it is a complex interaction between tweezer ergonomics, adhesive viscosity, and environmental variables.

This guide provides a deep dive into the mechanics of 0.03mm fiber manipulation. We will analyze why these fibers behave differently than 0.05mm or 0.07mm variants and provide a professional framework for eliminating slippage from your mega volume sets.

The Physics of Ultra-Fine PBT Fibers

To understand slippage, we must first look at the material properties of the fibers themselves. Most professional extensions, including the 0.07MM Cashmere Premium Mega Volume Eyelash Extensions (which we also provide in 0.03mm diameters), are made from high-quality PBT (Polybutylene Terephthalate).

At a 0.03mm diameter, the fiber has significantly less surface area and structural rigidity than a 0.07mm fiber. This means:

- Lower Friction: There is less surface area for the tweezer to "grab," making the fan more prone to shifting under uneven pressure.

- Increased Static: Thinner fibers are more susceptible to static electricity, especially in low-humidity environments. According to our internal scenario modeling, humidity levels below 45% can cause PBT fibers to repel each other, making it nearly impossible to maintain a cohesive fan base.

- Adhesive Displacement: Because the base of a 15D fan is incredibly dense, the adhesive must be able to "wick" into the center of the bundle. If the adhesive is too viscous, it sits on the outside, leaving the inner fibers dry and prone to slipping out once the fan is released.

Logic Summary: Our analysis of fiber behavior assumes that as diameter decreases, the ratio of surface area to volume changes, requiring a corresponding adjustment in mechanical grip and adhesive flow. This is a heuristic based on common patterns from customer support and technician feedback.

Tweezer Ergonomics: The "Lateral Pressure" Trap

The most common technical error we see in mega volume application is the application of excessive lateral pressure. When an artist feels a fan slipping, the natural instinct is to squeeze the tweezers harder. However, with high-precision mega volume tweezers, excessive lateral pressure often causes the tips to "splay" or bow outward.

For 0.03mm fibers, the "sweet spot" of a tweezer is often just a few millimeters wide. If you apply too much force at the handle, the tips may actually lose contact at the very point where they are holding the fibers.

The Correction: Vertical Squeezing Pressure

Instead of squeezing the tweezer arms together with brute force, focus on vertical, squeezing pressure directed at the base of the fan.

- The Technique: Position your tweezer tips so they are perfectly parallel to the lash strip. When you "pinch" or "pick up," the pressure should feel as though you are compressing the fibers into each other, rather than just clamping the metal shut.

- The Tool Check: Periodically check your tweezer alignment. Even a microscopic gap, invisible to the naked eye, can allow a 0.03mm fiber to slide through. We recommend using a "paper test"—if your tweezers cannot pick up a single 0.03mm fiber from the strip without it rotating, the tension needs adjustment.

The "Pre-Fan" Spoolie Hack

One of the most effective non-obvious tips for working with ultra-fine fibers is the "pre-fan" technique. Often, the adhesive used on the lash strip itself can be too "grabby" for 0.03mm fibers, causing them to clump or resist separation.

Before you begin your set, take a clean Clear Mascara Wands 50pcs/pack and gently back-comb the fibers on the strip.

- Why it works: This light mechanical action loosens the fibers from the strip adhesive without removing them. It also helps to "fluff" the tips, making it easier for your tweezers to isolate the exact number of fibers needed for a 10D or 15D fan.

- Sanitation Note: Consistent with guidelines from the CDC (Centers for Disease Control), always use a fresh, disposable wand for every client to prevent the cross-contamination of ocular pathogens.

Adhesive Chemistry and Wicking Mechanics

Adhesive selection is critical for 0.03mm work. Because the bases are so tight, you need an adhesive with a low viscosity (thin consistency). A thicker glue will "bead" at the base of the fan rather than penetrating the core.

The 0.5-1 Second Rule

For mega volume, we typically recommend an adhesive with a 0.5 to 1-second dry time.

- Wicking: A fast-setting, thin adhesive will "wick" up into the fan base instantly upon contact. This creates a "wrap" around the natural lash, locking the 0.03mm fibers into place.

- Slippage Prevention: If the glue dries too slowly, the fibers have time to shift or "bloom" (spread out) at the base before the bond is secure, leading to a weak attachment.

Safety and Compliance Warning: When choosing adhesives, professionals must be aware of chemical safety. A 2012 study published in PubMed (Amano et al.) highlighted that many early lash adhesives released significant formaldehyde and had pH levels that could cause keratoconjunctivitis. Modern professional formulas, like those we manufacture, are engineered to be pH-balanced and low-fume. Furthermore, ensure your supplies meet regional standards; for instance, Health Canada recently increased enforcement on cyanoacrylate-based products to ensure proper labeling and chemical safety.

Environmental Control: The Humidity Factor

As mentioned earlier, humidity is the "silent killer" of mega volume sets.

- High Humidity (>60%): The adhesive cures too fast. It may "shock cure" on the extension before you even reach the natural lash, leading to "pop-offs" or fans that slip off during the first brush-through.

- Low Humidity (<45%): Static electricity increases. The 0.03mm fibers will literally jump away from your tweezers or repel each other, causing the fan to "split."

Professional Tip: Invest in a high-quality hygrometer and a small humidifier for your lash room. Maintaining a consistent 50-55% humidity level is the "sweet spot" for most professional cyanoacrylate adhesives.

Hygiene and Long-Term Ocular Health

As a lash professional, your responsibility extends beyond the aesthetic. Troubleshooting slippage is also a matter of health. If fans are not properly bonded (due to slippage or poor adhesive choice), they can create "mechanical friction" against the eyelid.

According to the Mayo Clinic, poor lash hygiene and the buildup of bacteria or debris at the lash base is a primary cause of Blepharitis (eyelid inflammation). When fibers slip and create uneven, "crunchy" bases, it becomes much harder for the client to clean their lashes effectively.

Furthermore, a 2024 study in PMC (Ocular Surface Disease) found that long-term extension wear can alter the ocular surface microbiome. This reinforces the need for:

- Precise Application: No slippage, no "stickies" (multiple natural lashes stuck together).

- Proper Aftercare: Educating clients on using lash-safe cleansers.

- Quality Materials: Using FDA-compliant pigments and medical-grade PBT to minimize irritation.

Troubleshooting Scenario: The "Boxy Base"

| Symptom | Probable Cause | Expert Correction |

|---|---|---|

| Fibers sliding upward when pinched | Excessive lateral pressure; tweezer tips splaying | Shift pressure to a vertical "squeeze" at the fan base. |

| Fan "collapsing" during placement | Adhesive viscosity too high; glue not wicking | Switch to a thinner, faster-setting adhesive (0.5-1s). |

| Inner fibers falling out after set | "Dry" core in the fan base | Ensure the fan base is fully submerged in the adhesive drop. |

| Fibers repelling each other (splitting) | Low humidity/Static electricity | Increase room humidity to 50%+; use a nano-mister. |

Methodology Note: This troubleshooting table is a heuristic model derived from common technical failures observed in professional salon environments. It is intended as a diagnostic tool, not a substitute for formal hands-on training.

Advanced Alternatives: Premade and Easy Fanning

If you are a technician transitioning into mega volume and find that handmade 0.03mm fans are consistently slipping, there is no shame in utilizing engineered solutions.

The 0.05MM Easy Fanning Eyelash Extensions are designed with a microscopic amount of adhesive at the base of the strip. This prevents the fan from falling apart at the base while you are still perfecting your "pinch."

Alternatively, using 10D Handmade Loose Premade Fans Pointy Base(500 Fans) can eliminate the technical barrier of fan creation entirely. These fans are heat-bonded, meaning the base is ultra-slim and "locked," preventing any fiber slippage during application. This allows you to focus 100% of your attention on isolation and placement—the two most critical factors for client safety.

Summary of Best Practices

Mastering 0.03mm mega volume is a journey of precision. To eliminate fiber slippage, remember these core principles:

- Calibrate Your Touch: Use vertical squeezing pressure rather than horizontal force.

- Prepare the Strip: Use the "pre-fan" spoolie hack to loosen fibers.

- Match Your Chemistry: Use thin, fast-wicking adhesives for dense fans.

- Control Your Environment: Keep humidity between 50-55% to manage static and cure times.

- Prioritize Health: Follow American Academy of Ophthalmology (AAO) safety tips by ensuring clean applications that don't trap bacteria.

By addressing the mechanical and environmental causes of slippage, you will not only improve your technical speed but also provide a safer, more comfortable experience for your clients.

Disclaimer: This article is for informational purposes only and does not constitute professional medical or legal advice. Eyelash extension application should only be performed by licensed and trained professionals. If a client experiences a severe reaction, they should consult a medical professional immediately.

References

- CDC - Prevention of Conjunctivitis

- Mayo Clinic - Blepharitis Symptoms and Causes

- American Academy of Ophthalmology - Eyelash Extension Safety

- PubMed - Formaldehyde and pH in Eyelash Adhesives (Amano et al. 2012)

- Health Canada - Cosmetic Regulations for Cyanoacrylate Adhesives

- PMC - Ocular Surface Disease and Long-term Extension Wear (2024)