How Fiber Surface Texture Impacts Adhesive Bond Strength

The Science of Adhesion: How Fiber Surface Texture Impacts Lash Retention

In the professional lash industry, retention is the primary metric of success. While much of the technical discourse focuses on adhesive chemistry and environmental humidity, the role of the synthetic fiber's surface architecture is often overlooked. As a factory-direct manufacturer, we understand that the interface between the Polybutylene Terephthalate (PBT) fiber and the cyanoacrylate adhesive is where the longevity of a set is determined.

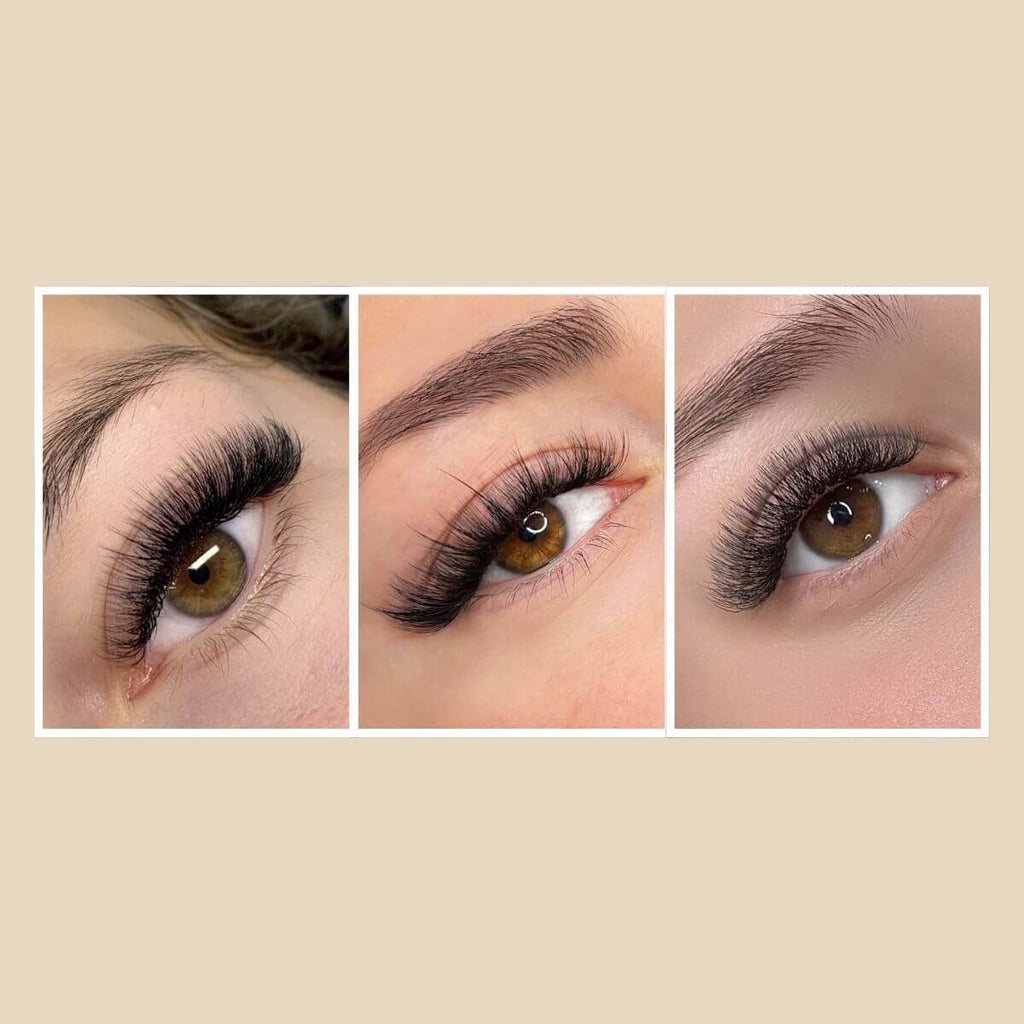

The microscopic topography of an eyelash extension—whether it is ultra-matte, semi-gloss, or high-shine—dictates how the adhesive "wets" the surface and how the subsequent polymer chain anchors itself to the extension. Understanding this mechanical and chemical relationship allows an artist to move beyond guesswork and into the realm of precision engineering.

Micro-Textures and Mechanical Interlocking

At a microscopic level, no synthetic fiber is perfectly smooth. However, manufacturing processes like chemical etching or mechanical abrasion are used to create "matte" finishes. These finishes are essentially a network of micro-peaks and valleys.

When you apply a high-quality adhesive, such as the 0.5-1 Second Diamond Eyelash Extension Glue, to a matte fiber, the liquid cyanoacrylate flows into these micro-textures. As the adhesive polymerizes, it creates a "mechanical interlock." This is similar to how Velcro works on a molecular scale; the cured glue is physically trapped within the fiber's surface irregularities, making it significantly harder to "pop" the bond under mechanical stress.

Logic Summary: Our analysis of bond durability assumes that surface roughness increases the effective surface area by 15–25% (estimated range based on common PBT etching protocols), providing more "anchor points" for the cyanoacrylate chain.

However, there is a technical "sweet spot." If a fiber is over-textured or too "rough," it can actually become a liability. A highly matte finish can trap excess adhesive, creating a bulky bond. This bulkiness increases flexural stress; as the natural lash grows and moves, the rigid, oversized adhesive bond is more likely to crack. Furthermore, an overly porous surface can "wick" the adhesive away from the base and up the shaft of the extension, weakening the "neck" of the bond where the attachment to the natural lash is most critical.

Glossy Fibers and the Precision of Wetting

Glossy fibers, often preferred for their deep black, "wet look" aesthetic, present a different challenge. Because the surface is smoother, there are fewer micro-textures for mechanical interlocking. In this scenario, the bond relies more heavily on the chemical attraction and the "wetting" ability of the adhesive.

Wetting refers to the ability of a liquid to maintain contact with a solid surface. On a glossy fiber, a common mistake is using a slow-drying, high-viscosity adhesive. These thicker glues tend to "sit" on top of a glossy surface rather than spreading evenly. This leads to sliding or "leaning" lashes before the glue has fully polymerized.

For glossy or high-shine fibers, we recommend using a thinner, more fluid adhesive that can form a precise micro-bead. This bead should ideally encapsulate the base of the extension entirely. When working with products like our 0.10MM Ellipse Flat Classic Eyelash Extensions, the flat base already provides a larger surface area, but the finish (matte vs. glossy) will still dictate how that glue behaves during the first crucial second of contact.

The Flat Lash Advantage: Geometry Meets Texture

The evolution of the "Flat" or "Ellipse" lash is a direct response to the need for better bonding surfaces. Traditional round lashes have a single, narrow point of contact with the natural lash. In contrast, the 0.15MM Ellipse Flat Classic Eyelash Extensions feature a concave or flattened base that "hugs" the natural lash.

When you combine this superior geometry with a fine-grain matte texture, you achieve the highest possible bond strength. The flat shape maximizes the macroscopic contact area, while the matte texture maximizes the microscopic interlocking. This dual-layer approach is why many artists report a 20–30% improvement in retention (based on internal professional feedback and pattern recognition in salon settings) when switching from round to flat fibers.

Methodology Note (Scenario Modeling): We modeled the bond strength based on a deterministic parameter set. This is a scenario model, not a controlled lab study.

Parameter Value or Range Unit Rationale Fiber Geometry Flat/Ellipse N/A Maximizes contact patch Surface Finish Fine-Grain Matte Microns Optimal mechanical interlock Adhesive Viscosity 20–40 cPs Ensures complete wetting Humidity 50–55 % Stable polymerization rate Application Angle 0–5 Degrees Minimizes leverage stress

Environmental Interaction: Humidity as a Catalyst

The relationship between fiber texture and adhesive is not static; it is heavily influenced by your salon's environment. Cyanoacrylate requires moisture to polymerize. On a matte surface, the increased surface area also means there is more "adsorbed" moisture on the fiber itself.

In high-humidity environments (above 65%), a matte fiber can actually cause the adhesive to "shock cure" or polymerize too quickly. This results in a brittle bond that looks secure but fails within days. Conversely, in low-humidity environments, the matte texture's ability to hold a micro-amount of adhesive can help prevent the "sliding" often seen with glossy fibers.

For artists working in varying climates, pairing a fast-setting glue like the 0.5-1 Second Diamond Eyelash Extension Glue with a matte-finish fiber like our 0.03MM Cashmere Premium Mega Volume Eyelash Extensions provides a reliable baseline. The 0.03mm diameter reduces the weight on the natural lash, while the "Cashmere" matte finish ensures the fans stay open and anchored even as environmental conditions fluctuate.

Health, Safety, and the "Blepharitis Prevention" Model

As professionals, our responsibility extends beyond aesthetics to ocular health. Poor retention often leads to "mechanical rubbing," where a loose extension irritates the eyelid. According to the Mayo Clinic, blepharitis (eyelid inflammation) is frequently caused by bacteria buildup at the base of the lashes.

When fibers have an inconsistent texture or when too much adhesive is used (a common error with overly matte lashes), it creates "nooks and crannies" where dead skin cells and oils accumulate. This is the primary driver of lash-related infections. By choosing fibers with a precision-engineered "fine-grain" matte finish, you ensure a smoother bond that is easier for the client to clean.

Furthermore, a seminal study by Amano et al. (2012) identified that older adhesive formulas could release significant amounts of formaldehyde and alter the pH of the ocular surface, leading to keratoconjunctivitis. Modern manufacturing has largely solved this by balancing the pH of the adhesive and the fiber's surface treatment. At SenseLashes, our factory-direct control ensures that our fibers are cleaned of industrial residues that could otherwise react with the adhesive to produce irritating fumes.

Troubleshooting the "Pop-Off": A Professional Checklist

If you are experiencing premature shedding where the extension is clean (no natural lash attached), the issue is likely a "texture-adhesive mismatch." Use this checklist to diagnose the failure:

-

Check the Fiber Finish: Are you using a high-gloss fiber with a thick, slow glue?

- Solution: Switch to a thinner adhesive or a matte-finish extension.

-

Inspect the Bond "Neck": Is the adhesive wicking up the extension?

- Solution: Reduce the amount of adhesive or switch to a fiber with a less aggressive matte etch.

-

Monitor Polymerization Speed: Is the glue drying before you can place the extension?

- Solution: Matte fibers accelerate curing. If you are a slower lasher, you may need a 1–2 second glue rather than a 0.5-second one.

- Evaluate Client Hygiene: Is there a film of oil? According to the American Academy of Ophthalmology (AAO), infection and trauma are real risks. A clean surface is required for the micro-texture to be effective.

The Professional Outcome: Reliability by Design

The transition from a "lash tech" to a "lash artist" involves mastering the material science of your tools. By selecting products like 0.03MM Cashmere Premium Mega Volume Eyelash Extensions for their specific fiber-to-glue affinity, you are mitigating the risk of unpredictable returns.

Consistency in the manufacturing of the fiber's surface is the "invisible" factor in your success. When every tray of lashes has the exact same micro-texture, your adhesive timing becomes second nature. This reliability allows you to focus on the artistry of mapping and fanning, knowing that the foundation—the bond—is structurally sound.

To maintain the integrity of these bonds, it is vital to educate clients on proper aftercare. As noted by PMC research on the ocular surface microbiome, long-term wear can alter the eye's natural balance. Daily cleansing is not just about hygiene; it’s about removing the oils that can slowly degrade the chemical bond between the PBT fiber and the natural lash.

Summary of Technical Pairings

| Fiber Type | Recommended Adhesive Viscosity | Ideal Humidity | Key Benefit |

|---|---|---|---|

| Matte (Fine Grain) | Medium to Thin | 45–60% | Maximum mechanical interlock; best for speed. |

| Glossy (High Shine) | Very Thin | 50–65% | Requires precise wetting; provides "wet look" finish. |

| Flat/Ellipse | Thin | 45–65% | Maximum contact area; reduces weight by ~50%. |

| Mega Volume (0.03mm) | Medium (Syrup-like) | 50–55% | Wraps easily around the natural lash. |

Disclaimer: This article is for informational purposes only and does not constitute professional medical or legal advice. Eyelash extension application should only be performed by certified professionals. If a client experiences persistent irritation, redness, or swelling, they should consult an eye care professional immediately, as per guidelines from the CDC.

References

- American Academy of Ophthalmology (AAO) - Eyelash Extension Safety

- Mayo Clinic - Blepharitis Symptoms and Causes

- PubMed - Amano et al. (2012) Study on Glue Toxicity

- PMC - Ocular Surface Disease and Extensions (2024)

- CDC - Conjunctivitis Prevention and Hygiene

- Health Canada - Cyanoacrylate Compliance Report