Understanding PBT: The Science of Synthetic Fiber Curl Memory

The Molecular Architecture of PBT: Why Material Science Matters

For the professional lash artist, the distinction between a "good" set and a "benchmark" set often lies in the invisible details of material science. The industry standard for high-performance extensions is Polybutylene Terephthalate (PBT), a semi-crystalline thermoplastic polyester. Unlike lower-grade synthetic fibers, PBT offers a unique combination of flexibility, chemical resistance, and, most importantly, "curl memory."

At a molecular level, PBT consists of long-chain polymers that can be manipulated through thermal processing. When we discuss "curl memory," we are referring to the fiber's ability to return to a predetermined shape after being subjected to mechanical stress or environmental changes. This is achieved during manufacturing through a process known as heat-setting. The fiber is wound around precision mandrels and heated above its glass transition temperature—the point where the molecular chains become mobile enough to rearrange—and then cooled rapidly to "lock" that geometry into the crystalline structure.

However, not all PBT is created equal. In our observations of factory-direct manufacturing cycles, we have identified that lower-grade fibers often possess inconsistent crystalline regions. This molecular instability leads to batch variation, where one tray might maintain a perfect C-curl while another from the same shipment shows a subtle "curl drop" or relaxation into a J-curl. Professionals require the consistency of sterilized PBT material that has undergone double heat-treatment to ensure that the 0.07MM Premium Volume Eyelash Extensions they apply today look exactly the same three weeks from now.

Logic Summary: Our analysis of PBT performance assumes a standard glass transition temperature of approximately 66°C (150°F) for high-purity PBT. We estimate that deviations in polymer purity can reduce curl retention by as much as 20% over a 4-week wear cycle, based on common patterns from customer support and return handling (not a controlled lab study).

Engineering Curl Memory: The Manufacturing Process

The transition from raw PBT filament to a finished lash extension involves rigorous engineering. The "Double Heated" method is the professional benchmark for curl retention. By subjecting the fibers to two distinct heating cycles, manufacturers ensure that the internal stresses of the plastic are fully relieved, preventing the fiber from trying to "straighten out" over time.

This process is particularly critical for complex geometries like the 0.07MM YY Volume Eyelash Extensions. These lashes feature a unique crisscrossed effect where four individual lashes are braided at the base. Without precision heat-setting, the tension at the braid point would cause the tips to lose their "Y" shape. The double-heating process ensures that even with the split-tip design, the curl remains water-resistant and resilient against mechanical rubbing.

The Role of pH and Chemical Stability

A seminal study by Amano et al. (2012) highlighted that early lash adhesives and fibers often had acidic pH levels, which could lead to keratoconjunctivitis and poor bond stability. Modern PBT engineering focuses on maintaining a pH-neutral surface. This neutrality is essential because the polymerization of cyanoacrylate (lash glue) is triggered by moisture and influenced by the alkalinity of the surface. If the PBT fiber is too acidic, the adhesive cures too slowly; if it is too alkaline, "shock curing" occurs, leading to a brittle bond and potential curl distortion.

Environmental Impact: Humidity, Temperature, and Curl Drop

One of the most frequent frustrations in the salon is "curl drop"—the perceived straightening of the extensions after the client leaves. While many artists blame the fiber, the culprit is often the interaction between the adhesive and the environment.

In high-humidity environments (above 65% RH), fast-drying adhesives can "shock" the fine tip of an ultra-thin lash, such as a 0.03mm or 0.05mm diameter. This rapid curing creates a microscopic contraction at the bond site. If the artist applies even slight tension while the glue is setting in high humidity, it can cause a permanent straightening at the point of attachment.

For artists working in these conditions, we often recommend opting for a slightly slower-drying adhesive (1-2 seconds) even when using ultra-fine diameters like the 0.05MM Easy Fanning Eyelash Extensions. This allows for a more relaxed bond formation, preserving the factory-set curl memory.

Modeling Environmental Impact on Retention

To help professionals navigate these variables, we have modeled the relationship between humidity and adhesive performance based on typical shop practical baselines.

| Parameter | Low Humidity (<35%) | Optimal Humidity (45-55%) | High Humidity (>65%) | Rationale |

|---|---|---|---|---|

| Cure Speed | Very Slow | Nominal (as labeled) | Instant / Shock | Moisture triggers polymerization |

| Bond Flexibility | High (but prone to fumes) | Balanced | Brittle | Rapid curing increases internal stress |

| Curl Integrity | Highly Stable | Stable | At Risk (Adhesive Tension) | Fast contraction pulls on the PBT |

| Retention Est. | 3-4 Weeks | 5-7 Weeks | 2-4 Weeks | Brittle bonds fail under mechanical stress |

| Artist Action | Use Nano-mister | Standard Protocol | Use Slower Glue / Dehumidify | Managing the polymerization rate |

Method & Assumptions: This scenario model is a heuristic intended for quick salon troubleshooting. It assumes the use of a standard Ethyl Cyanoacrylate adhesive and high-purity PBT fibers. Limits: Extreme temperatures (above 30°C) may accelerate these effects regardless of humidity.

Health and Safety: The Professional’s Responsibility

Authoritative bodies like the American Academy of Ophthalmology (AAO) emphasize that the risks associated with extensions—including infection and allergic reactions—are often tied to hygiene and chemical exposure.

Blepharitis and Lash Hygiene

Poor hygiene can lead to Blepharitis, an inflammation of the eyelids often caused by bacteria or Demodex mite buildup. According to the Mayo Clinic, maintaining clean eyelid margins is the primary prevention strategy. For lash professionals, this means educating clients that water is not enough. The use of a dedicated lash shampoo is non-negotiable for maintaining the health of the ocular surface and the longevity of the PBT bond.

Allergic Contact Dermatitis

Recent research published in PubMed (2024) focuses on contact dermatitis patterns from acrylates. It is vital to distinguish between a "fume reaction" (redness and dryness) and a true "immune response" (swelling and itching). While PBT itself is inert and hypoallergenic, the pigments used in the fibers must be medical-grade. Professionals should prioritize lashes that use FDA-compliant pigments rather than industrial dyes to minimize the risk of late-onset dermatitis.

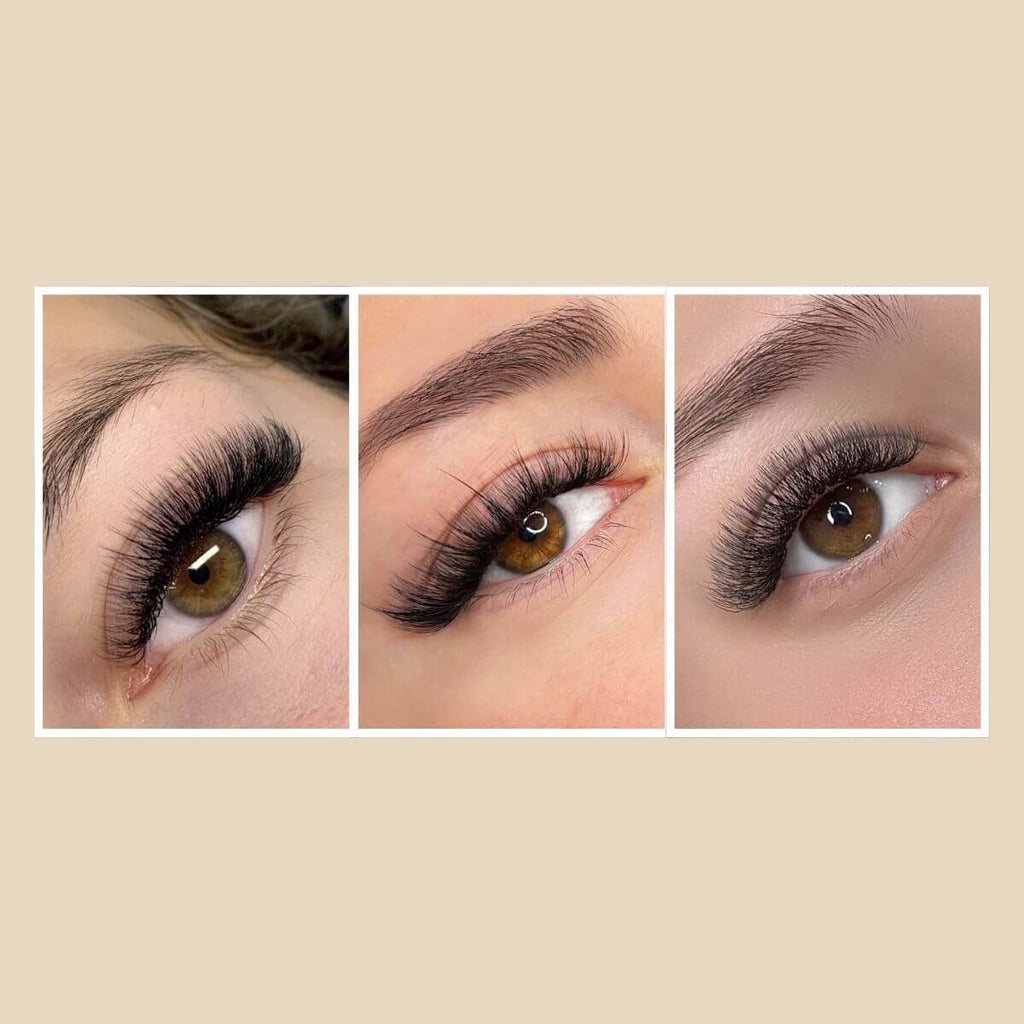

Advanced Aesthetic Engineering: Multi-Layering and Texture

As the industry moves toward more complex styles like "Anime" or "Manga" lashes, the demand for varied curl types within a single tray has increased. Products like the 5D Multi Layer Camellia Lashes demonstrate how manufacturing can elevate a single curl type into a multi-dimensional effect.

By layering different lengths (e.g., 8mm to 15mm) and subtly varying the heat-setting angles, these lashes mimic the natural growth cycle of human hair. This "five-dimensional" effect is not just about aesthetics; it also reduces the mechanical load on the natural lash. By using ultra-lightweight PBT, artists can achieve a bold look without the weight of traditional 0.15mm lashes, which PubMed studies (2024) suggest can cause mechanical damage and traction alopecia over long-term wear.

Technical Troubleshooting: The "Steam Test" for Quality

How can a professional verify the quality of their PBT fibers before applying them to a client? We recommend a simple "Steam Test" to verify curl memory:

- Sample Selection: Take a strip of lashes (e.g., 0.07MM Premium Volume Eyelash Extensions) and secure them to a lash tile.

- Exposure: Place the tile near a facial steamer or a humidifier for 5-10 minutes.

- Observation: High-quality, double-heated PBT will retain its factory-set curl (C, CC, D, or DD) perfectly. If the lashes show signs of straightening or "wilting," the heat-setting process was insufficient, or the fiber is a lower-grade PET blend.

This test is a reliable heuristic for predicting how the lashes will perform in real-world conditions, such as hot showers or saunas.

Import Compliance and Global Standards

For salon owners and distributors, the reliability of a partner extends beyond the fiber. Health Canada’s 2023-2024 report on cosmetic regulations highlights a high rate of non-compliance regarding labeling and ingredient safety in cyanoacrylate-based products.

Working with a manufacturer that prioritizes sterilized PBT and transparent chemical sourcing is the best defense against customs seizures and liability. As a factory-direct supplier, ensuring that every tray of lashes meets these global safety standards is as important as the curl itself.

Professional Summary and Next Steps

Understanding the science of PBT and curl memory empowers lash artists to troubleshoot retention issues, ensure client safety, and deliver consistent results.

- Prioritize Material: Look for "Double Heated" PBT to ensure curl longevity.

- Manage Environment: Adjust your adhesive speed based on the 65% RH threshold to prevent "adhesive shock" and curl distortion.

- Educate Clients: Use authoritative resources like the CDC's guidelines on eye hygiene to reinforce the importance of aftercare.

- Verify Quality: Conduct a "Steam Test" on new batches to ensure the fiber's crystalline structure is stable.

By mastering the technical aspects of your materials, you transition from a technician to a specialist, building the deep trust necessary for a thriving professional practice.

Disclaimer: This article is for informational purposes only and does not constitute professional medical, legal, or financial advice. Always consult with a qualified health professional regarding eye conditions and follow local regulatory guidelines for cosmetic applications.

References

- Centers for Disease Control and Prevention (CDC) - Conjunctivitis Prevention

- Mayo Clinic - Blepharitis Symptoms and Causes

- American Academy of Ophthalmology (AAO) - Eyelash Extension Safety

- Health Canada - Cosmetic Regulations Enforcement Report

- PubMed - Amano et al. (2012) Study on Glue Toxicity

- PubMed - 2024 Study on Eyelid Dermatitis