Why Professional Lashes Lose Curl: Diagnosing Fiber Relaxation

The Professional’s Guide to Curl Retention: Understanding Fiber Relaxation

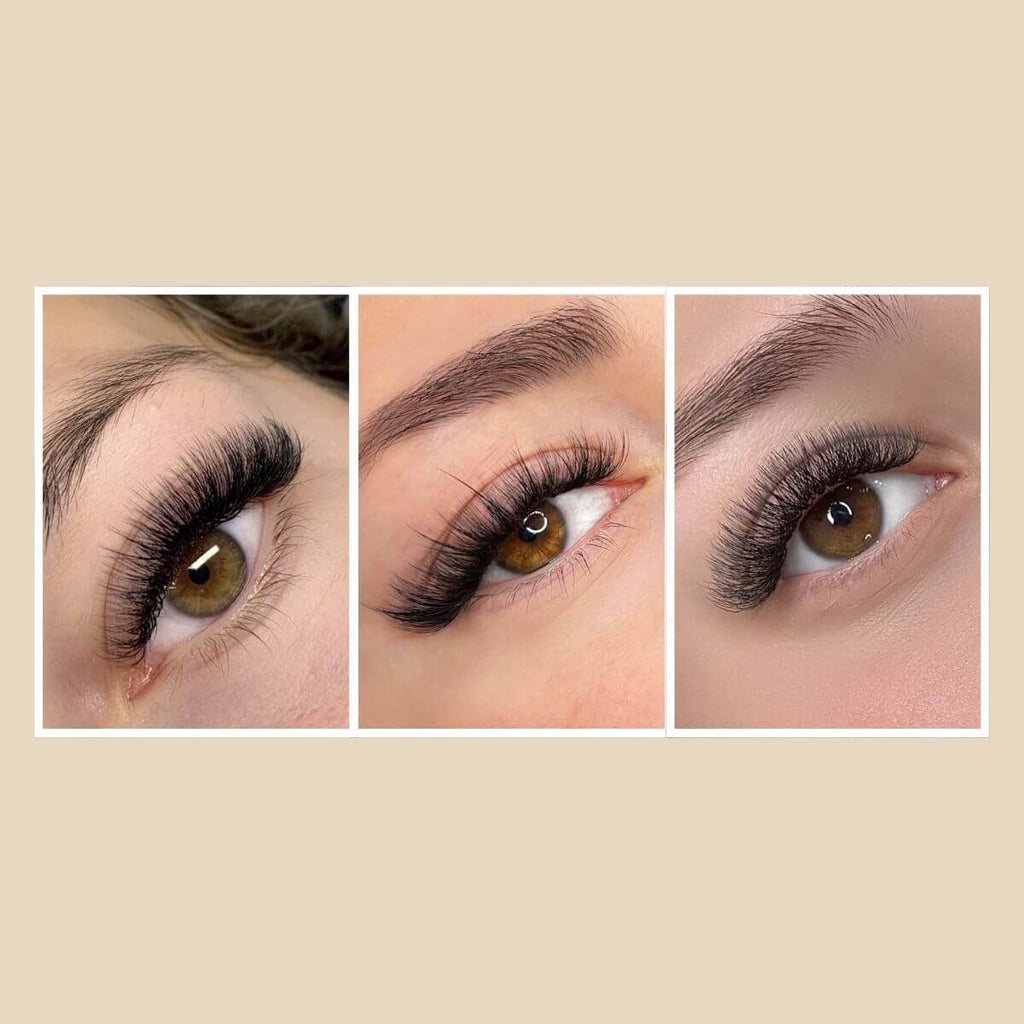

For a professional lash artist, few issues are as frustrating as a client returning 48 hours after a set with "straight" lashes. You applied a perfect D-curl, yet the extensions now resemble a B-curl. This phenomenon, known as fiber relaxation or "curl drop," is a technical challenge that bridges the gap between material science and environmental variables.

Understanding why professional lashes lose their curl requires a deep dive into the engineering of synthetic fibers, the chemistry of adhesives, and the physiological impact of the ocular environment. This guide provides a definitive diagnostic framework for identifying whether curl failure stems from manufacturing inconsistencies, environmental stressors, or procedural errors.

The Engineering of Curl Memory: How PBT Fibers Work

Most professional eyelash extensions are manufactured from Polybutylene Terephthalate (PBT), a high-performance thermoplastic. The "curl" is not a natural state for this material; it is engineered through a rigorous heat-setting process. During manufacturing, PBT fibers are wrapped around high-precision glass or metal rods and subjected to specific temperatures to "reset" the polymer chains into a permanent shape.

However, not all PBT is created equal. The quality of the raw material and the duration of the heat-setting cycle determine the "curl memory." If the temperature is too low or the cooling phase is too rapid, the polymer chains remain under internal tension, seeking any opportunity to return to their original, straighter state.

The Role of Fiber Texture: Matte vs. Gloss

Observations from high-volume salons suggest that the surface finish of a fiber significantly impacts its resilience. Lashes with a pronounced matte finish, such as the 0.05mm Royal Sable Mega Volume Eyelash Extensions(Super Black, Super Matte), often demonstrate superior curl stability in high-humidity environments.

The micro-texture of a matte fiber may interact differently with ambient moisture compared to high-gloss fibers. While high-gloss fibers are often coated with a silicone-based sealant for shine, this coating can sometimes act as a lubricant under heat and moisture, allowing the internal structure of the PBT to relax more easily.

Diagnosing the Root Cause: Product vs. Environment

When curl drop occurs, technicians often blame the product immediately. However, the interaction between the adhesive and the environment is frequently the true culprit.

The 65% Humidity Heuristic

To determine if a batch of lashes is defective, we recommend a controlled stress test. This is a standard heuristic used by senior technicians to audit new inventory.

Logic Summary (Batch Testing): Our modeling of fiber performance assumes that a stable PBT fiber should withstand moderate environmental shifts. This test isolates the product from the application variables.

The 24-Hour Stress Test Protocol:

- Create 5-10 fans using a new tray.

- Adhere them to a practice strip using your standard adhesive.

- Place the strip in a controlled environment with 65% humidity (use a hygrometer to verify).

- After 24 hours, measure the curl angle.

| Parameter | Threshold | Unit | Rationale |

|---|---|---|---|

| Humidity Level | 65 | % | Mimics high-stress summer/tropical conditions |

| Exposure Time | 24 | Hours | Sufficient for initial polymer relaxation |

| Max Allowable Drop | 10-15 | Degrees | Industry standard for "stable" curl memory |

| Fiber Diameter | 0.03 - 0.07 | mm | Thinner fibers are more susceptible to relaxation |

| Temperature | 22 - 24 | °C | Standard salon operating temperature |

If the lashes lose more than 15 degrees of their curl angle under these conditions without any external mechanical force, the issue likely lies in the manufacturing heat-setting process.

The Adhesive Factor: Curing Speed and Base Stability

One of the most misunderstood aspects of curl retention is the role of the adhesive. The adhesive does more than just bond the extension to the natural lash; it acts as a structural "anchor" for the base of the fan.

In high-humidity environments, cyanoacrylate-based adhesives cure significantly faster. If you use an ultra-fast adhesive (e.g., 0.5-second dry time) when your room humidity is above 60%, the adhesive may "shock cure." This results in a brittle bond that fails to fully encapsulate the base of the extension.

When the base is not securely locked, the mechanical tension of the curl itself can cause the fiber to "untwist" or relax at the point of attachment. This is why we often see curl drop manifesting within 48-72 hours—the time it takes for the adhesive to reach its full internal crystalline structure.

Pro Tip: Match your adhesive speed to your environment. In higher humidity, switching to a slightly slower-drying glue allows the adhesive to wrap around the fiber properly, providing the structural support needed to maintain the curl's tension.

Health, Hygiene, and Fiber Degradation

While manufacturing and chemistry play massive roles, the client's ocular health and hygiene habits cannot be ignored. According to the Mayo Clinic, conditions like Blepharitis (eyelid inflammation) are often caused by bacteria buildup at the lash line.

Bacteria and natural skin oils (sebum) are surprisingly corrosive to synthetic fibers and adhesives. If a client does not clean their lashes daily, the accumulation of oils can soften the PBT fiber over time, leading to premature relaxation. This is particularly true for "Mega Volume" sets where the density of the fans can trap more debris.

The Science of "Lash Shampoo" as Prevention

We advocate for a shift in perspective: Lash Shampoo is not just a cosmetic cleaner; it is a tool for "Blepharitis Prevention" and curl preservation. Research published in PMC (Ocular Surface Changes) highlights how extensions can affect tear film stability. When the tear film is compromised, the eye may produce excess lipids, which further degrade the lash bond and the fiber's structural integrity.

Educating clients on daily washing with a professional-grade foam cleanser ensures that the pH of the ocular surface remains balanced. According to the CDC's guidelines on eye hygiene, maintaining a sterile environment is the first line of defense against infections that could lead to the premature removal of a set.

Advanced Troubleshooting: Mechanical Stress and Chemical Exposure

Sometimes, curl drop isn't "relaxation" but mechanical damage. A case study in PMC (Corneal Abrasion Case) notes that mechanical rubbing of extensions against the eye or during the removal process can cause trauma to both the natural lash and the extension.

The Impact of 0.03mm Fibers

As the industry moves toward lighter diameters, such as the 0.03MM Cashmere Premium Mega Volume Eyelash Extensions, the risk of mechanical deformation increases. While these lashes are safer for natural lash health—as supported by a 2024 PubMed study on ocular disorders—their extreme fineness means they have less "mass" to resist external heat (like steam from a shower or oven).

Logic Summary (Mechanical Sensitivity):

- Assumption: 0.03mm fibers have a higher surface-area-to-volume ratio than 0.15mm fibers.

- Inference: They absorb ambient heat faster, making them more susceptible to "re-shaping" if the client is exposed to high temperatures shortly after application.

The Chemistry of Allergic Reactions and Irritation

Technicians must be able to distinguish between a product failure (like curl drop) and a biological reaction. A study on Allergic Contact Dermatitis caused by Ethyl Cyanoacrylate reminds us that what looks like a "bad batch" of lashes might actually be a client's immune response.

When a client experiences swelling or redness, they often rub their eyes. This mechanical friction is a leading cause of distorted curls. By implementing a strict "Patch Test Protocol," as suggested by recent research on Eyelid Dermatitis, you can mitigate these risks and protect your professional reputation.

Maintaining Standards: A Salon Sanitation SOP

To ensure consistent results and minimize "curl drop" complaints, every salon should operate under a strict Standard Operating Procedure (SOP). This SOP should be grounded in authoritative safety data to bridge the "compliance signaling gap."

- Inventory Quarantine: Test every new batch of lashes using the 65% humidity heuristic before using them on clients.

- Environmental Control: Use a dehumidifier or humidifier to maintain a salon range of 45-55% humidity.

- Adhesive Rotation: Replace adhesives every 4 weeks to prevent changes in viscosity and curing speed that can affect curl stability.

- Client Education: Provide a "Client Safety Consent Form" based on AAO (American Academy of Ophthalmology) guidelines, emphasizing the link between hygiene and retention.

Why Quality Matters: The SenseLashes Difference

At the manufacturing level, the difference between a lash that holds its curl and one that fails often comes down to the quality of the PBT and the precision of the heat-setting equipment. For example, the 0.07mm Royal Sable Volume Eyelash Extensions(Super Black, Super Matte) are engineered with a specific polymer blend that mimics the softness of cashmere while retaining the structural "spring" of a silk lash.

By choosing products that prioritize manufacturing rigor, such as the 0.03mm Royal Sable Mega Volume Eyelash Extensions(Super Black, Super Matte), technicians can reduce the variables that lead to fiber relaxation.

Summary Checklist for Technicians

If you are facing curl retention issues, work through this checklist before discarding your inventory:

- Check Room Humidity: Is it above 60%? If so, your adhesive might be shock-curing.

- Evaluate Fiber Finish: Are you using high-gloss lashes? Consider switching to a matte fiber for better environmental resistance.

- Audit Client Aftercare: Are they using a professional lash shampoo? Oils are the enemy of curl memory.

- Perform a Stress Test: Use the 24-hour, 65% humidity protocol to isolate the product performance.

- Review Adhesive Speed: Ensure your glue's dry time is appropriate for your current salon conditions.

Final Thoughts for the Professional

Curl drop is rarely the result of a single factor. It is usually a "perfect storm" of high humidity, fast-curing adhesive, and perhaps a slight inconsistency in the fiber's heat-treatment. By adopting a scientific approach to diagnosis—grounded in the principles of polymer science and ocular health—you can provide your clients with the consistent, high-performance results they expect.

Disclaimer: This article is for informational purposes only and does not constitute professional medical or legal advice. Always consult with a qualified health professional regarding eye conditions and adhere to local cosmetic regulations.

References

- Centers for Disease Control and Prevention (CDC) - Conjunctivitis Prevention

- Mayo Clinic - Blepharitis Symptoms and Causes

- American Academy of Ophthalmology (AAO) - Eyelash Extension Safety

- PubMed - Allergic Contact Dermatitis from Cyanoacrylate

- PMC - Ocular Surface Changes and Eyelash Extensions

- Health Canada - Cosmetic Regulations Enforcement Report