Standardizing Student Kits: Patch Test Protocols for Educators

The Educator’s Mandate: Safety as a Standard

In the rapidly evolving landscape of the lash industry, technical skill alone no longer defines a premier educator. As the market expands—projected to maintain a significant CAGR through 2025 according to Grand View Research—the distinction between a "technician" and a "professional" lies in the mastery of risk management. For lash academies, the student kit is the first and most critical touchpoint for establishing this professional rigor.

We believe that standardizing student kits is not merely about inventory management; it is about eliminating variables. When every student in a cohort uses the exact same adhesive batch, the same lash diameter, and the same preparation protocol, educators can troubleshoot complications with scientific precision. This article provides a benchmark-level framework for educators to standardize their training kits and implement a repeatable patch testing SOP that prioritizes client safety and academy credibility.

The Chemistry of Risk: Why Standardization Matters

To teach safety, one must understand the chemical mechanisms at play. The primary culprit in lash-related adverse reactions is Ethyl Cyanoacrylate. A 2024 study published in PubMed highlights that contact dermatitis patterns from acrylate-containing cosmetics are becoming more complex, often involving delayed immune responses.

Historically, the industry has struggled with high rates of non-compliance regarding labeling and chemical safety. Health Canada’s 2023-2024 Enforcement Report revealed significant discrepancies in cyanoacrylate-based adhesives. For an educator, providing a kit with unverified or "white-label" adhesives of unknown origin is a liability. By standardizing on a factory-direct, compliant adhesive, you ensure that students are learning with tools that meet international safety thresholds.

Logic Summary: Our recommendation for adhesive standardization is based on the "Control Variable" heuristic. In a training environment, if five students report client redness, but they are using five different adhesive brands, the educator cannot determine if the issue is technique-related or product-fault. Standardizing the kit allows for a "Common Batch" analysis.

Standardizing the Student Kit: The "Control" Components

A student kit should be designed to reduce mechanical and chemical stress during the learning phase. We recommend educators standardize the following components to ensure consistent patch test results and application outcomes:

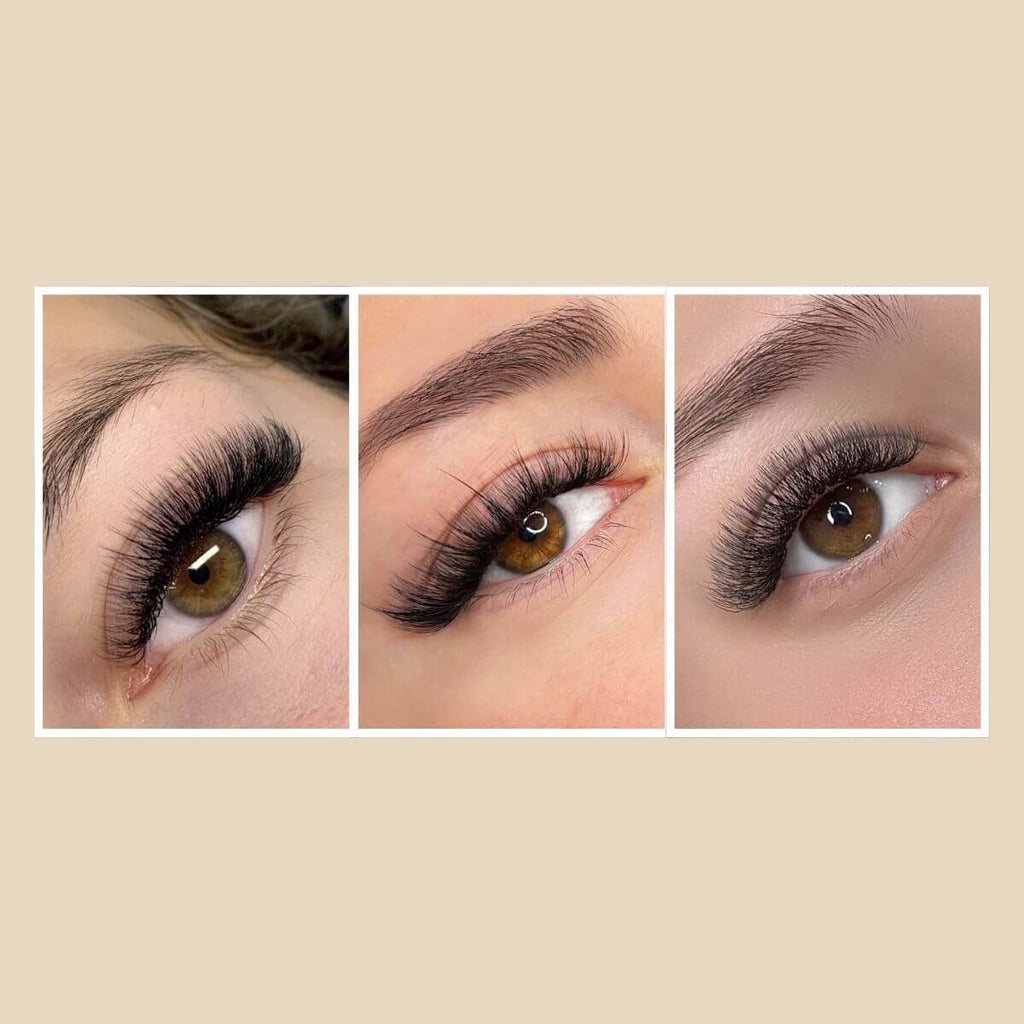

1. The Universal Test Lash

Students often make the mistake of testing with one lash type and applying another. We advise standardizing on a moderate-diameter fiber for all initial training and testing. The 0.10MM Ellipse Flat Classic Eyelash Extensions are an ideal "control" lash. Because they provide a larger bonding area with less weight than traditional round fibers, they reduce mechanical strain on the natural lash, allowing the student to isolate chemical sensitivity more accurately.

2. High-Visibility Consumables

Hygiene is the foundation of safety. According to the CDC, preventing the spread of conjunctivitis requires strict adherence to disposable tool protocols. Standardizing kits with high-visibility tools, such as Clear Mascara Wands, allows educators to visually verify that students are using fresh, uncontaminated tools for every client.

3. The Volume Entry Fiber

For students transitioning to volume, the 0.07MM Easy Fanning Eyelash Extensions provide a consistent base. In a patch test scenario, using an easy-fan lash ensures that the student isn't struggling with fan symmetry, which can lead to excessive adhesive usage—a common cause of chemical irritation.

The Definitive Patch Test Protocol (SOP)

A "negative" patch test is not a guarantee of safety, but a standardized protocol significantly reduces the "compliance signaling gap." Educators should teach the following 48-hour protocol as a non-negotiable industry standard.

Step 1: Site Selection and Preparation

While many technicians use the skin behind the ear, we often observe that in dry climates, the inner forearm provides a more reliable surface for monitoring adherence and localized redness.

| Feature | Behind the Ear | Inner Forearm |

|---|---|---|

| Sensitivity | High (Good for rapid reactions) | Moderate |

| Visibility | Low (Difficult for client to monitor) | High (Easy to photograph/track) |

| Friction Risk | High (Hair/Glasses) | Low |

| Recommended For | Standard Testing | High-Precision Monitoring |

Step 2: The "Three-Lash" Application

Instead of a single drop of adhesive on the skin (which does not simulate the application environment), students should apply 3–5 extensions to the outer corner of each eye, or to the natural hair on the forearm. This simulates the actual vapor exposure and mechanical weight.

Step 3: The 48-Hour Observation Window

According to the American Academy of Ophthalmology (AAO), allergic reactions to acrylates can manifest 24 to 48 hours after exposure.

- 24-Hour Check: Client performs a visual self-check for itching or swelling.

- 48-Hour Check: Final professional verification before the full set.

Methodology Note (Modeling): This protocol assumes a "worst-case" scenario for Type IV hypersensitivity. By requiring a 48-hour window, we are modeling our safety standards after clinical dermatological patch tests, which typically peak at the 48-72 hour mark.

Documentation: The Educator’s Shield

Professional diligence is best demonstrated through documentation. Educators must teach students to record more than just "Pass/Fail." A defensible record includes:

- Adhesive Batch Number: To track potential manufacturer recalls.

- Environmental Conditions: Humidity and temperature during the test (high humidity can accelerate curing and increase fume intensity).

- Placement Map: Exactly where the test lashes were applied.

This level of detail prepares students for high-stakes professional environments and protects the academy from liability. For further reading on why a negative result isn't a 100% guarantee, see our guide on Patch Test Limitations.

Troubleshooting: Irritation vs. Allergy

One of the most valuable skills an educator can impart is the ability to distinguish between chemical irritation and a true allergic reaction.

Chemical Irritation (Fumes)

Often caused by the "curing" process. As identified by Amano et al. (2012), the release of formaldehyde during polymerization can cause keratoconjunctivitis. This usually presents as immediate redness or a "bloodshot" appearance that dissipates within 24 hours.

Allergic Contact Dermatitis (Immune Response)

This is an immune system reaction to the acrylate itself. Symptoms include swelling of the eyelid (blepharitis-like symptoms), intense itching, and weeping skin. This reaction typically worsens over time and requires the immediate removal of the extensions.

For clients complaining of "burning" without visible swelling, educators should refer to guides on Dry Eye Syndrome. Often, what is perceived as a "glue allergy" is actually an exacerbation of pre-existing dry eye caused by the lash fumes or poor lid hygiene.

The Role of Aftercare in Safety Training

Safety does not end when the client leaves the chair. Educators must emphasize that poor hygiene is a leading cause of eyelid inflammation. The Mayo Clinic notes that blepharitis is often caused by bacteria buildup at the lid margin.

In your student kits, include a sample of professional lash shampoo and teach students to market it as "Blepharitis Prevention" rather than just a cleanser. This shift in language positions the artist as a health-conscious professional. Research in PMC shows that extensions can affect tear film stability; therefore, teaching students to use Clear Mascara Wands to gently groom lashes without disrupting the meibomian glands is crucial for long-term ocular health.

Compliance Signaling: Positioning Your Academy

By adopting these rigorous standards, your academy signals to the industry that you prioritize eye health over sales. Using resources like the FDA’s Eye Cosmetic Safety guidelines to author your "Client Safety Consent Forms" provides a layer of medical authority that "home-grown" forms lack.

Furthermore, utilizing high-quality fibers like 0.07MM Cashmere Premium Mega Volume Eyelash Extensions in advanced kits demonstrates a commitment to weight-reduction. As noted in PubMed (2024), mechanical damage from heavy extensions is a significant risk factor for traction alopecia of the natural lash. Providing lightweight 0.03mm or 0.07mm options teaches students the "Health-First" fanning technique.

Summary of Standardization Benefits

Implementing a standardized kit and patch test protocol offers three primary advantages for the lash educator:

- Reduced Liability: Standardized SOPs and compliant products minimize the risk of severe reactions and legal disputes.

- Enhanced Learning Curve: By eliminating product variables, students can focus entirely on mastering their isolation and placement techniques.

- Professional Authority: Academies that teach medical-grade hygiene and chemical safety produce more successful, high-earning graduates.

As you build your 2025 curriculum, remember that the tools you put in your students' hands today will define the safety standards of the industry tomorrow. By choosing factory-direct, compliant supplies and enforcing a rigorous patch test protocol, you are not just teaching a craft—you are building a legacy of professional excellence.

Disclaimer: This article is for informational and educational purposes only and does not constitute medical or legal advice. Lash extension application involves chemical adhesives and proximity to the eyes, which carries inherent risks. Always consult with a qualified medical professional regarding eye health concerns and adhere to local licensing and safety regulations.

References & Sources

- CDC: Conjunctivitis Prevention and Hygiene

- American Academy of Ophthalmology: Eyelash Extension Safety

- Mayo Clinic: Blepharitis Symptoms and Causes

- Health Canada: 2023-2024 Cosmetic Regulation Enforcement Report

- PubMed: Contact Dermatitis from Acrylate-Containing Cosmetics (2024)

- FDA: Eye Cosmetic Safety Overview