Environmental Impact on Curl: How Heat and Steam Affect PBT

Understanding the Material Science of PBT in Eyelash Extensions

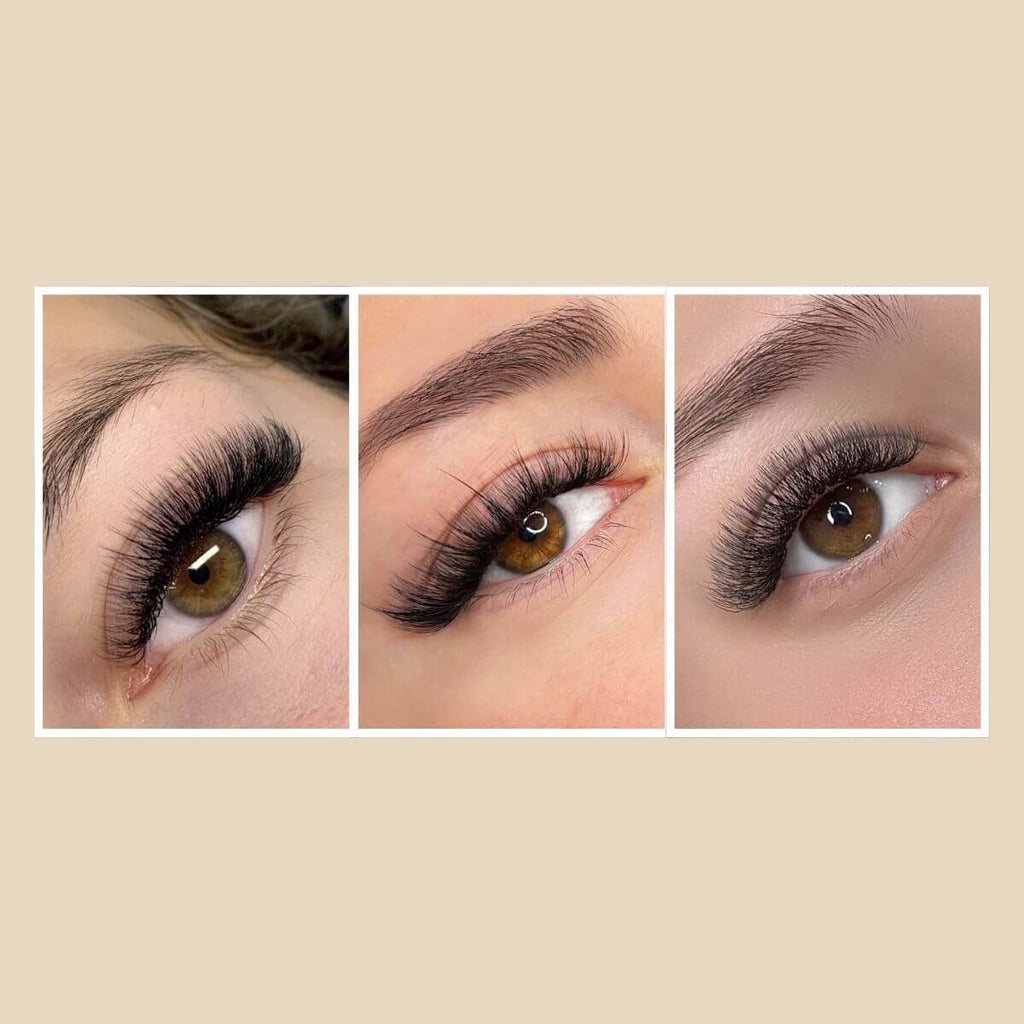

The global eyelash extension market is projected to witness significant growth through 2025, driven by a professional shift toward high-performance synthetic materials. According to market analysis by Grand View Research, the demand for individual synthetic extensions continues to outpace traditional strips, placing a premium on the technical consistency of the fibers used. For the professional lash artist, the primary material of choice is Polybutylene Terephthalate (PBT).

PBT is a high-performance thermoplastic semi-crystalline polymer. In the context of lash manufacturing, it is prized for its "curl memory"—the ability to retain a specific shape after being heat-treated. However, as a thermoplastic, PBT remains sensitive to thermal fluctuations post-manufacturing. Understanding the physical limits of these fibers when exposed to heat and steam is not merely a matter of aesthetics; it is a fundamental component of professional risk management and client satisfaction.

The Mechanism of Curl Drop: How Heat Resets PBT Memory

The "curl" in a lash extension is achieved through a process called heat-setting. During manufacturing, straight PBT fibers are wrapped around glass or metal rods and subjected to high temperatures in an industrial oven. This process realigns the polymer chains, "locking" them into the desired curvature (e.g., J, B, C, CC, D, or U curl).

However, this memory is not absolute. If the extensions are subsequently exposed to temperatures approaching the material’s glass transition zone or subjected to high-pressure steam, the polymer chains gain enough kinetic energy to begin "relaxing." This results in what the industry terms "curl drop" or "curl relaxation."

Environmental Stressors and Curl Deformation

Professional observations from artists operating in high-humidity coastal regions or tropical climates suggest that environmental factors can significantly degrade the structural integrity of the curl.

Modeling Note: Curl Retention Heuristics Our analysis of curl performance in high-stress environments is based on common patterns from customer support and professional feedback (not a controlled lab study). We utilize the following heuristics for studio management:

- The Humidity Lift Rule: In climates with consistent relative humidity (RH) above 70%, standard C-curl lashes can lose an estimated 15-20% of their vertical lift within the first 48 hours if the studio lacks adequate dehumidification.

- The Thermal Working Time Rule: For every 5°C (9°F) the studio temperature rises above the baseline of 25°C (77°F), the effective working time for cyanoacrylate adhesive is reduced, and the risk of pre-application curl relaxation in stored lashes increases.

| Environmental Factor | Impact on PBT Fiber | Professional Risk |

|---|---|---|

| High Ambient Heat (>30°C) | Accelerates polymer relaxation | Permanent loss of curl "snap" |

| Direct Steam/Sauna | Breaks temporary hydrogen bonds | Immediate curl straightening |

| Fluctuating Humidity | Affects adhesive curing speed | Poor retention and "crunchy" bases |

| UV Exposure | Potential polymer degradation | Fiber brittleness over long-term wear |

The Role of Steam: Why "Waterproof" Doesn't Mean "Steam-Proof"

A common misconception among clients—and some novice artists—is that because extensions are waterproof, they are immune to the effects of water in all forms. While PBT is hydrophobic (it does not absorb water), steam introduces two variables: heat and moisture-driven pressure.

When a client uses a sauna, a hot shower, or a facial steamer, the combination of high temperature and water vapor acts as a mild "re-setting" agent. For clients who frequent these environments, the use of high-diameter, heavy lashes can exacerbate the issue, as the weight of the extension pulls against the relaxing polymer.

To mitigate this, seasoned professionals often employ an adaptive technique. For clients who prioritize high-heat activities, using a slightly tighter curl (e.g., opting for a D-curl when a C-curl aesthetic is desired) compensates for the expected relaxation. Furthermore, prioritizing lightweight fibers, such as 0.05MM Cashmere Premium Mega Volume Eyelash Extensions, reduces the mechanical stress on the natural lash during the relaxation phase.

Adhesive Chemistry and Environmental Interference

The environment doesn't just affect the PBT fiber; it radically alters the behavior of the adhesive. Most professional lash glues are based on Ethyl Cyanoacrylate, a chemical that requires moisture (humidity) to polymerize.

According to a report by Health Canada, technical compliance regarding labeling and chemical safety is critical, as improper storage or environmental exposure can lead to adhesive degradation. If the humidity is too high, the glue cures too fast ("shock curing"), leading to a brittle bond and poor retention. If the humidity is too low, the glue stays liquid longer, increasing the risk of chemical irritation or "blooming" (white residue).

Troubleshooting Chemical Sensitivity

Environmental factors can also exacerbate health risks. High heat increases the volatility of cyanoacrylate, leading to higher fume concentrations. This can be confused with a dry eye condition or a true allergic reaction.

- Dry Eyes: As noted by WebMD, dry eye syndrome can cause burning sensations that mimic glue sensitivity.

- Allergic Dermatitis: A study published in PubMed highlights that Ethyl Cyanoacrylate can cause allergic contact dermatitis.

- Formaldehyde Risks: Historical data from Amano et al. (2012) identified that older glue formulas could release formaldehyde and had acidic pH levels that caused keratoconjunctivitis. Modern, professional-grade formulas are typically pH-balanced to avoid such ocular trauma.

Clinical Implications of Poor Lash Hygiene

While heat and steam affect the product's aesthetic performance, the client's post-application behavior affects their ocular health. The belief that lashes should not be touched or washed to "preserve the curl" is a dangerous fallacy.

The Mayo Clinic identifies Blepharitis—eyelid inflammation—as a common consequence of poor hygiene. When clients avoid washing their lashes to protect the curl from water, they allow oils, dead skin, and bacteria to accumulate. This creates an ideal environment for Demodex mites. Research on Demodex mite infestation confirms that ocular hygiene is non-negotiable for long-term lash health.

The Salon Sanitation SOP (Standard Operating Procedure)

To bridge the gap between product performance and client safety, salons must implement strict sanitation protocols aligned with CDC guidelines.

- Disposable Consumables: Use single-use wands and patches for every client to prevent cross-contamination.

- Client Education: Explicitly instruct clients that "water is not enough." A dedicated lash shampoo is required to break down oils without compromising the adhesive bond.

- Environmental Control: Maintain a studio temperature of 21°C–24°C (70°F–75°F) and humidity between 45%–55%. Use a calibrated hygrometer to monitor these levels in real-time.

Logic Summary: Our recommendation for these specific ranges is based on the optimal polymerization rate of Ethyl Cyanoacrylate and the thermal stability thresholds of PBT fibers observed in professional manufacturing settings.

Material Selection: Cashmere vs. Royal Sable

Choosing the right fiber is the first line of defense against environmental curl drop. Not all PBT is created equal; the finishing processes and fiber density play a role in how the lash stands up to heat.

- Cashmere Fibers: Products like 0.07MM Cashmere Premium Mega Volume Eyelash Extensions are engineered for extreme softness and a "matte black" finish. Because they are lighter than traditional synthetic mink, they are less prone to mechanical "droop" when exposed to high humidity.

- Royal Sable Fibers: For artists seeking a balance between flexibility and a deep, dark finish, 0.07mm Royal Sable Volume Eyelash Extensions(Super Black, Super Matte) offer a slightly more rigid structure that can provide better curl resilience in temperate climates.

Long-term Effects on the Ocular Surface

Recent 2024 investigations into ocular surface changes suggest that long-term extension wear can alter the microbiome of the eye and affect tear film stability. This makes the "aftercare sealant" more than just a retail add-on; it is a protective barrier.

A high-quality sealant helps to "lock in" the adhesive bond and provides a hydrophobic coating over the PBT fiber, which can marginally improve curl retention by reducing the direct impact of ambient moisture on the polymer chains.

Mechanical Damage and Fiber Weight

The American Academy of Ophthalmology (AAO) warns against the risks of traction alopecia caused by excessively heavy extensions. In environments where curl drop is a known issue, artists may be tempted to use thicker lashes to "hold the shape." This is a counter-productive strategy. Instead, moving toward thinner diameters (0.03mm to 0.05mm) allows for fuller sets with less weight, protecting the natural lash from mechanical damage while maintaining the desired aesthetic even if slight relaxation occurs.

Professional Storage and Inventory Management

Expertise in lash artistry extends to how products are handled before they ever reach the client's eyes. Because PBT is a thermoplastic, storage conditions are paramount.

- The Car Trap: Never leave lash trays in a vehicle. On a day where the outside temperature is 27°C (80°F), the interior of a car can reach 40°C+ (100°F+) within minutes. This is sufficient to cause permanent, uneven curl deformation across an entire inventory.

- The Bathroom Mistake: Storing lashes in a bathroom exposes them to frequent bursts of high-pressure steam. This can degrade the "tack" of the lash strip and begin the relaxation process of the fibers.

- Optimal Storage: Keep inventory in a cool, dark, and dry environment. A dedicated airtight container with silica gel packets is the professional standard for preserving curl integrity.

Summary of Best Practices for Challenging Climates

For professionals operating in high-heat or high-humidity zones, consistency is achieved through adaptation rather than resistance.

- Audit the Environment: Use a hygrometer. If humidity exceeds 60%, invest in a professional-grade dehumidifier.

- Adjust the Mapping: If a client has a history of "straightening" lashes, move up one curl level (e.g., C to CC) or use a "L" or "M" curl, which often have more stable bases.

- Prioritize Fiber Quality: Use premium PBT fibers like 0.05mm Royal Sable Mega Volume Eyelash Extensions(Super Black, Super Matte) which are manufactured with advanced heat-treatment protocols to ensure batch-to-batch consistency.

- Educate the Client: Provide a clear "Aftercare SOP" that explains why saunas and steam rooms should be avoided for the first 48 hours, and why daily cleansing is mandatory for both health and retention.

By understanding the material science of PBT and the chemical constraints of adhesives, lash artists can transition from "service providers" to "technical experts," reducing post-sale misunderstandings and building a reputation for reliability in any climate.

Disclaimer: This article is for informational purposes only and does not constitute professional medical or legal advice. Eyelash extension application involves chemicals and proximity to the ocular area; always follow local regulations, maintain proper certification, and consult with an ophthalmologist if ocular irritation occurs.

References

- Centers for Disease Control and Prevention (CDC) - Conjunctivitis Prevention

- Mayo Clinic - Blepharitis Symptoms & Causes

- American Academy of Ophthalmology (AAO) - Eyelash Extension Safety

- Health Canada - Cosmetic Regulations Enforcement Report

- PubMed - Allergic Contact Dermatitis from Ethyl Cyanoacrylate

- PMC - Ocular Surface Disease and Eyelash Extensions

- Grand View Research - False Eyelashes Market Size & Share