Synthetic Fiber Elasticity: Solving the Problem of Drooping Fans

The Science of Curl Retention: Understanding Synthetic Fiber Elasticity

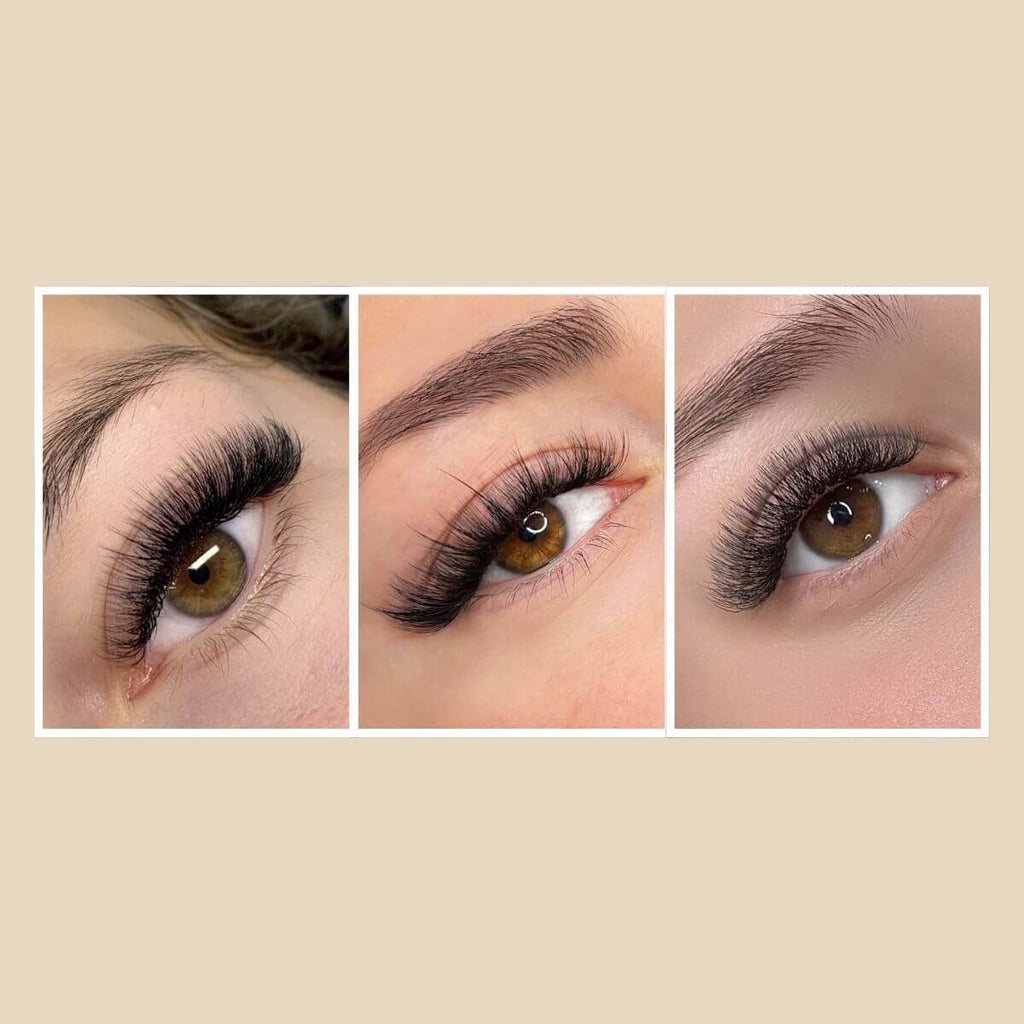

For a professional lash artist, few things are as frustrating as a perfectly crafted volume fan that "droops" or collapses before it even reaches the client's natural lash. This phenomenon, often dismissed as a technique error or a "bad batch" of adhesive, is frequently rooted in the material science of the lash fiber itself. When working with Mega Volume techniques, the margin for error is razor-thin. If the synthetic fiber lacks the necessary elasticity—the ability to return to its original shape after being manipulated—the aesthetic integrity and the longevity of the set are compromised.

The industry relies heavily on PBT (Polybutylene Terephthalate) fibers. However, not all PBT is created equal. The difference between a high-performance fiber and a budget alternative lies in the polymer alignment and the multi-stage heat-setting process used during manufacturing. Understanding these technical nuances is essential for salon owners who prioritize predictable outcomes and professional-grade consistency.

The Chemistry of Fiber Elasticity and Polymer Alignment

At the molecular level, synthetic lash fibers are composed of long polymer chains. In high-quality PBT fibers, these chains are precisely aligned through a controlled extrusion and cooling process. This alignment creates a "molecular memory" that allows the fiber to maintain its curl even under the mechanical stress of fanning and the chemical exposure of adhesives.

Lower-grade fibers often suffer from inconsistent polymer alignment. During the manufacturing process, if the heat-setting is rushed or the cooling is uneven, the fiber becomes prone to "memory fatigue." This means that once you use your tweezers to "pinch" or "wiggle" a fan open, the internal structure of the fiber begins to fail. Within 30 to 60 seconds, the fan may start to close or lose its symmetrical spread.

Logic Summary: Our analysis of fiber performance assumes a standard PBT polymer base. We model "memory fatigue" as a localized structural failure in the polymer chain caused by insufficient thermal stabilization during the manufacturing phase (based on common manufacturing heuristics).

The "Pinch Test" Heuristic

To verify the elasticity of your inventory, we recommend a practical shop-floor heuristic known as the "Pinch Test." Take a single fan or a small grouping of fibers, pinch them into a fan shape using your preferred volume technique, and hold for 10 seconds. Upon release, a well-engineered lash—such as the 0.03mm Royal Sable Mega Volume Eyelash Extensions(Super Black, Super Matte)—should spring back to 80-90% of its original open state. If the fan collapses by more than 50% or remains permanently deformed, the fiber elasticity is likely insufficient for advanced volume work.

Environmental Impacts on Fiber Integrity

While manufacturing quality is the foundation, environmental factors in the salon can significantly alter fiber behavior. High humidity is a known catalyst for "drooping fans," but not for the reason most artists think. While humidity affects adhesive curing speed, it can also "plasticize" certain fiber coatings.

When fibers are stored in environments with relative humidity consistently above 60%, the moisture can interact with the surface treatments applied to the PBT. This can permanently reduce the inherent "springback" of the lash. Even if the core polymer is sound, the softened coating creates enough friction to prevent the fibers from sliding past each other during the fanning process, leading to "sticky" fans that refuse to stay open.

Modeling Note (Reproducible Parameters):

Parameter Value or Range Unit Rationale / Source Category Storage Humidity 45–55% RH Ideal range to prevent coating plasticization. Storage Temperature 20–23 °C Maintains polymer stability. Exposure Window < 60 Seconds Maximum time a fan should remain open before placement. Fiber Diameter 0.03–0.07 mm Common range for volume and mega volume. Elasticity Recovery 80–90 % Target springback for professional-grade fibers.

Why "Water is Not Enough": The Health Argument for High-Quality Materials

The technical performance of a lash fiber is inextricably linked to the health of the client's ocular surface. Drooping or collapsing fans often lead to a "heavy" base, which can trap debris and bacteria more easily than a clean, open fan. According to the Mayo Clinic, Blepharitis (eyelid inflammation) is frequently caused by bacteria buildup at the base of the lashes.

When fans close shortly after application, they create a denser surface area that is harder for the client to clean. This makes the use of a dedicated lash shampoo non-negotiable. However, the first line of defense is using fibers that stay open and "fluffy," allowing for better airflow and easier access for cleansing.

Preventing Ocular Surface Changes

Recent research published in PMC (2024) highlights how eyelash extensions can affect tear film stability. If a lash artist uses low-quality, heavy fibers (e.g., traditional 0.15mm fibers instead of lightweight 0.03mm or 0.05mm options), the mechanical weight can disrupt the meibomian glands, which produce the oily layer of the tear film.

Using ultra-lightweight fibers like the 0.03MM Cashmere Premium Mega Volume Eyelash Extensions minimizes this mechanical risk. These "Fan Like Butter" fibers are designed to provide maximum density with minimum weight, protecting the client's long-term eye health while ensuring the aesthetic remains consistent.

Technical Troubleshooting: Solving the Drooping Fan

If you are experiencing drooping fans despite using high-quality products, consider the following technical adjustments:

- Check Your Mapping and Weight: Ensure the length and diameter of the extensions are appropriate for the natural lash. Overweighting the natural lash can cause the entire fan to sag, which is often mistaken for fiber failure. According to a 2024 study on PubMed, mechanical damage from extensions is a leading cause of traction alopecia in the lash line.

- Evaluate Application Speed: If your adhesive dries too slowly, the fan may close before the bond is secure. Conversely, if you are working too slowly for your adhesive's "open time," you may be manipulating the fan past its elastic limit.

- Adhesive pH and Chemical Sensitivity: The PubMed study by Amano et al. (2012) noted that the pH of some adhesives can cause irritation. While modern formulas are more balanced, the chemical interaction between the adhesive and the fiber coating can sometimes affect curl retention. Using a neutral-pH primer can help stabilize the bond without compromising fiber integrity.

The Role of Premade Fans in Consistency

For artists struggling with consistency or time constraints, high-quality premade fans offer a solution to the "drooping" problem. Products like the 14D Handmade Loose Premade Fans Pointy Base(500 Fans) are heat-bonded at the base. This manufacturing process "locks" the fan into an open position, eliminating the risk of memory fatigue during application.

Methodology Note: Our recommendation for premade fans is based on the observation that heat-bonded bases provide a more stable mechanical structure than adhesive-bonded bases, reducing the likelihood of fan collapse during the "pick and place" phase (based on pattern recognition from professional technician feedback).

Salon Sanitation and Client Safety: The Professional Standard

Consistency isn't just about the look; it's about the safety protocol. The CDC (Centers for Disease Control) provides clear guidelines on preventing the spread of conjunctivitis, which is vital for any lash professional. Using disposable consumables and ensuring that your fibers are stored in a dust-free, humidity-controlled environment is part of a professional Standard Operating Procedure (SOP).

Managing Allergic Reactions

It is crucial to distinguish between irritation and a true allergy. A PubMed study on Dermatitis (2022) explains that Ethyl Cyanoacrylate, the main ingredient in most lash glues, can cause allergic contact dermatitis. If a client experiences drooping lashes accompanied by eyelid swelling, this is likely an immune response rather than a fiber failure.

To mitigate these risks, the American Academy of Ophthalmology (AAO) recommends a thorough consultation and patch testing. We suggest implementing a "Patch Test Protocol" where you apply a few fans of high-quality fibers—such as 0.05mm Royal Sable Mega Volume Eyelash Extensions(Super Black, Super Matte)—48 hours before a full set to monitor for delayed reactions.

The Importance of Professional-Grade Removal

When a set reaches the end of its life cycle, or if a client experiences an adverse reaction, the removal process must be handled with extreme care. Mechanical rubbing or the use of liquid removers can lead to corneal abrasions. A case report in PMC (2023) details how improper removal techniques can cause significant ocular trauma.

We advocate for the use of non-drip Cream Removers over liquid alternatives. Cream formulas stay exactly where they are placed, dissolving the adhesive bond without running into the client's eyes, thereby reducing the risk of chemical burns and mechanical injury.

Summary of Technical Best Practices

To ensure your volume fans remain open, symmetrical, and healthy for the client, follow this technical checklist:

- Fiber Selection: Prioritize multi-stage heat-set PBT fibers with high elasticity.

- The Pinch Test: Regularly audit your inventory for memory fatigue.

- Climate Control: Maintain salon humidity between 45% and 55% to protect fiber coatings.

- Weight Management: Use 0.03mm or 0.05mm diameters for Mega Volume to protect the meibomian glands.

- Hygiene SOP: Implement daily lash washing to prevent Blepharitis and maintain fan fluffiness.

- Compliance Awareness: Stay updated on import regulations and ingredient safety, such as the Health Canada (2023-2024) report on cyanoacrylate labeling.

By focusing on the material science of fiber elasticity and adhering to rigorous safety standards, lash artists can move beyond the frustration of "drooping fans" and deliver the consistent, high-performance results that define a premier salon.

Disclaimer: This article is for informational purposes only and does not constitute professional medical, legal, or financial advice. Eyelash extension application involves risks of infection, allergic reaction, and ocular injury. Always consult with a qualified health professional if you or your clients experience persistent eye irritation or symptoms of an allergic reaction.

References

- CDC - Conjunctivitis Prevention

- Mayo Clinic - Blepharitis Symptoms and Causes

- American Academy of Ophthalmology - Eyelash Extension Safety

- PubMed - Ocular Disorders and Eyelash Extensions (2024)

- PMC - Tear Film Stability and Extensions (2024)

- Health Canada - Cosmetic Regulations Summary (2023-2024)

- PubMed - Allergic Contact Dermatitis from Acrylates (2022)

- PMC - Corneal Abrasion Case Report (2023)