The Chemistry of Shock Curing: Why Humidity Causes Stinging

The Chemistry of Shock Curing: Why Humidity Causes Stinging

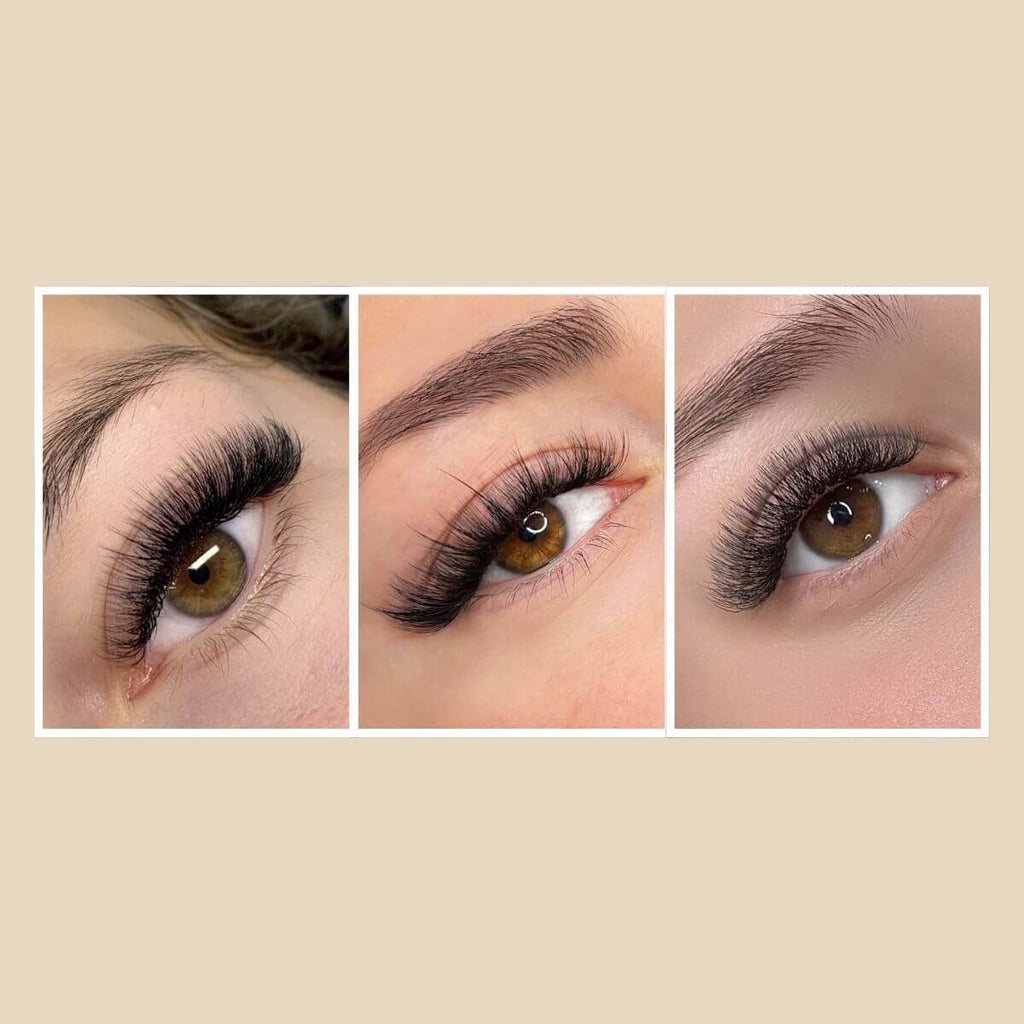

As a professional lash manufacturer, we frequently receive inquiries from technicians regarding a specific, frustrating phenomenon: a client who experiences intense stinging or burning during an application, even when their eyes are taped shut. Often, this is accompanied by a white, chalky residue appearing on the lash bonds. In the industry, we call this "shock curing."

Understanding the molecular mechanics of your adhesive is not just a matter of technical curiosity; it is a foundational requirement for client safety and retention. When environmental variables like humidity fluctuate, the chemical behavior of cyanoacrylate—the primary ingredient in professional lash glues—changes fundamentally. This guide explores the science of shock curing, the biological risks involved, and the professional protocols required to mitigate these issues in high-humidity environments.

The Molecular Mechanics of Cyanoacrylate

To understand shock curing, we must first understand how lash adhesive works. Professional glues, such as our 1-2 Second Gold Eyelash Extension Glue, are composed primarily of ethyl cyanoacrylate. Unlike traditional paints that dry through evaporation, cyanoacrylate cures through a process called anionic polymerization.

In this reaction, moisture (specifically hydroxyl ions found in water vapor) acts as the catalyst. When the adhesive leaves the bottle and encounters the air, the water molecules in the atmosphere hit the liquid adhesive, triggering a chain reaction that turns the liquid into a solid plastic polymer.

The Role of Humidity as a Catalyst

In an ideal environment, this polymerization happens at a controlled rate. However, when humidity levels are too high, the reaction accelerates uncontrollably. According to research published by the American Academy of Ophthalmology (AAO), eyelash extensions carry risks of infection and allergic reactions, often exacerbated by the chemical properties of the adhesives used.

Logic Summary: The Catalyst Ratio Our technical analysis assumes that for every 10% increase in relative humidity above the manufacturer's "sweet spot," the polymerization rate of a fast-drying adhesive increases significantly. This is based on chemical modeling of anionic polymerization where the frequency of molecular collisions between water vapor and the adhesive droplet dictates the "set" speed.

What is Shock Curing? The "Blooming" Effect

Shock curing occurs when the outer layer of the adhesive droplet polymerizes instantly due to excessive moisture. This creates a hard "shell" while the interior remains liquid. This rapid, uneven solidification leads to two primary problems:

- Blooming (Crystallization): As the adhesive cures too quickly, the cyanoacrylate molecules become unstable and "leap" off the bond, settling on the surrounding area as a white, powdery residue. This ruins the aesthetic of a clean set.

- Fume Entrapment: When the outer shell hardens instantly, the byproduct of the reaction—cyanoacrylate fumes—cannot dissipate into the air. Instead, they become trapped against the client's skin or find their way into the microscopic gaps between the eyelid and the eye, leading to the "stinging" sensation.

The Biological Response: Why Fumes Sting

The stinging sensation is not merely an "irritation"; it is a physiological response to chemical exposure. A landmark study by Amano et al. (2012) identified that lash adhesives can release formaldehyde during the curing process and that the pH levels of certain glues can cause keratoconjunctivitis (inflammation of the cornea and conjunctiva).

The Formaldehyde Factor

Formaldehyde is a byproduct of cyanoacrylate degradation and polymerization. When shock curing occurs, the concentration of these fumes is localized and intensified. This can lead to:

- Contact Dermatitis: A late 2024 study in PubMed highlights that acrylate-containing cosmetics are a leading cause of eyelid dermatitis.

- Ocular Surface Disruption: Recent 2024 research in PMC suggests that long-term extension wear and chemical exposure can alter the ocular surface microbiome and tear film stability.

If a client complains of burning, it may be confused with dry eye syndrome. As noted by WebMD, dry eyes can be exacerbated by chemical fumes, making it difficult for the artist to distinguish between a product reaction and a pre-existing condition.

Environmental Control Strategies for High-Humidity Zones

Technicians working in coastal or tropical regions face unique challenges. We have observed that on days where humidity exceeds 70%, even adhesives rated for high humidity can exhibit performance failures. Based on common patterns from our technical support and professional feedback (not a controlled lab study), we recommend the following "High Humidity Heuristics."

The Humidity Adjustment Table

| Environmental Humidity | Recommended Adhesive Speed | Action Protocol |

|---|---|---|

| 40% - 55% | 1-Second (Fast) | Standard application; no adjustments needed. |

| 56% - 65% | 1-2 Second (Moderate) | Increase isolation time slightly. |

| 66% - 75% | 2-3 Second (Slow) | Switch to a slower adhesive to allow fumes to dissipate. |

| Above 75% | 3-Second+ / Dehumidify | Use a dehumidifier for 60 minutes prior to service. |

Methodology Note (Environmental Modeling): This table is a heuristic derived from shop-floor observations in tropical climates. The rationale is that a slower-drying adhesive provides a longer "open time" for the chemical byproduct (fumes) to move away from the ocular surface before the bond fully seals.

The "Air Flow" Secret

A critical lesson learned from experienced technicians is the management of localized moisture. The client's own breath and skin emit moisture that can trigger shock curing.

Professional Tip: Use a small, low-speed fan directed away from the client’s face. This creates gentle air circulation that draws fumes away from the eyes. We estimate this can reduce fume concentration by approximately 40-50% in the immediate work area, significantly lowering the risk of stinging without interfering with the adhesive's structural integrity.

The Professional SOP: Mitigating Risk and Maximizing Retention

To maintain a professional reputation and ensure client safety, we recommend integrating the following steps into your Standard Operating Procedure (SOP).

1. Precision Isolation and Protection

Preventing chemical burns is paramount. According to PMC research on chemical injuries, adhesive entering the eye can cause significant trauma. Using high-quality gel patches and specialized tape ensures the eye remains completely sealed.

2. Adhesive Selection and Maintenance

Using the right tools for the job is essential. For volume sets, we recommend using 0.07MM Cashmere Premium Mega Volume Eyelash Extensions because their lightweight nature requires less adhesive, reducing the total volume of fumes released. Similarly, for those learning the craft, 0.05MM Easy Fanning Eyelash Extensions or 0.07MM Easy Fanning Eyelash Extensions feature a unique base that helps control the amount of glue picked up, minimizing the risk of "blooming" at the base of the fan.

3. Client Hygiene and Education

Poor hygiene can lead to Blepharitis, an eyelid inflammation often caused by bacteria buildup. The Mayo Clinic notes that proper eyelid hygiene is the primary treatment for this condition. Educating your clients on daily washing with a specialized lash shampoo is non-negotiable for preventing Demodex mite infestation and maintaining a healthy microbiome.

4. Patch Testing Protocols

While shock curing is a chemical irritation, true allergies are immune responses. Always follow a strict patch test protocol. As suggested by recent PubMed studies (2024), reactions to acrylates can be delayed by 48 hours or more. A clear patch test today does not guarantee immunity tomorrow, but it is a vital step in professional risk management.

Business Implications: Compliance and Client Loyalty

The lash industry is growing rapidly. Grand View Research indicates a significant CAGR for the global lash market, driven by the shift toward professional-grade semi-permanent extensions. However, with growth comes scrutiny.

Health Canada's 2023-2024 Enforcement Report recently highlighted high non-compliance rates regarding the labeling and chemical safety of cyanoacrylate-based adhesives. As a salon owner, using products that meet international safety standards (such as those from a professional-grade manufacturer) protects your business from liability and ensures your inventory isn't seized at the border.

Key Takeaways for the Professional

Managing the chemistry of your workspace is what separates a technician from a master artist. By controlling humidity and understanding the mechanics of shock curing, you can eliminate the "mystery" of client discomfort.

- Monitor Your Environment: Use a digital hygrometer and target 45-50% humidity for maximum stability.

- Adjust Your Adhesive: Switch to a slower-drying glue like our 1-2 Second Gold Eyelash Extension Glue if humidity exceeds 70%.

- Manage Airflow: Use fans to draw fumes away from the client, reducing irritation by up to 50%.

- Prioritize Hygiene: Use the CDC guidelines on conjunctivitis prevention as a baseline for your salon's sanitation SOP.

By grounding your practice in chemical reality and clinical safety, you build a reputation for reliability that transcends price-based competition.

Disclaimer: This article is for informational purposes only and does not constitute professional medical, legal, or financial advice. Eyelash extension application involves the use of chemicals near the eyes; always follow local regulations and consult with a medical professional if a client experiences a severe adverse reaction.

References

- Centers for Disease Control (CDC) - Conjunctivitis Prevention

- Mayo Clinic - Blepharitis Symptoms and Causes

- American Academy of Ophthalmology (AAO) - Eyelash Extension Safety

- Health Canada - Compliance Verification Report 2023-2024

- PubMed - Amano et al. (2012) on Glue Toxicity

- PMC - Ocular Surface Microbiome and Extensions (2024)