Decoding Cyanoacrylate Fumes: Why Irritation Occurs

Decoding Cyanoacrylate Fumes: Why Irritation Occurs

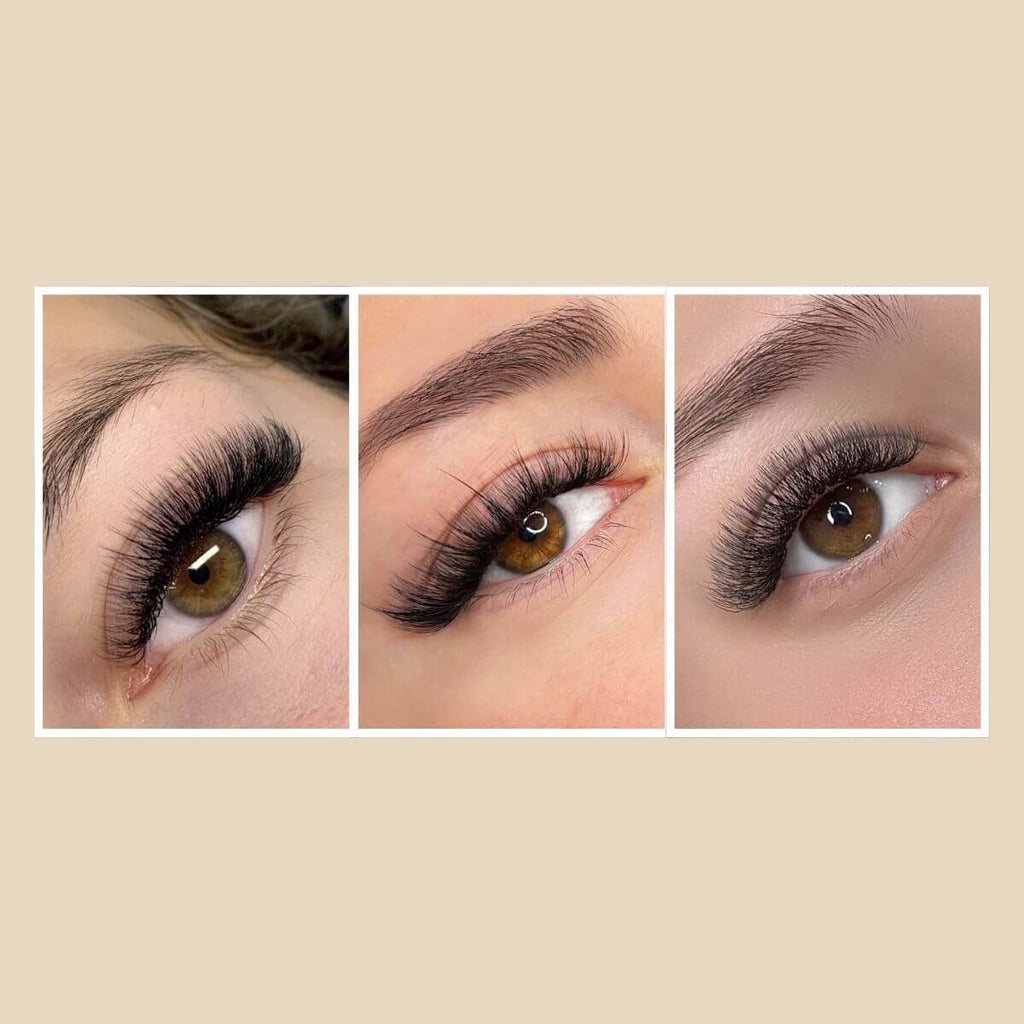

For the professional lash artist, the chemistry of adhesion is as critical as the artistry of the set. While we focus on perfect isolation and symmetrical fanning, the invisible behavior of cyanoacrylate—the primary component in professional lash adhesives—dictates the safety and comfort of the client. Understanding why fumes cause irritation is not merely a matter of comfort; it is a fundamental requirement for managing operational risk and ensuring long-term ocular health.

Irritation, often characterized by redness, watering, or a "gritty" sensation, is frequently misunderstood. It is often conflated with allergic reactions, yet the two are driven by entirely different biological mechanisms. This guide provides a technical breakdown of how cyanoacrylate vapors interact with the ocular surface and provides evidence-based strategies to mitigate these effects.

The Chemistry of Cyanoacrylate and Vapor Pressure

Cyanoacrylate is an acrylic resin that cures through a process called anionic polymerization. Unlike traditional glues that dry through evaporation, lash adhesive requires a nucleophile—specifically moisture (H2O)—to trigger a chemical chain reaction that transforms the liquid into a solid polymer.

In its liquid state, cyanoacrylate is highly volatile. This volatility leads to the release of vapors, commonly referred to as "fumes." These vapors are essentially monomers looking for moisture to begin the curing process. Because the ocular surface is naturally moist, it becomes a primary target for these airborne monomers.

The Role of Formaldehyde and pH

A landmark study by Amano et al. (2012) identified that older generations of adhesives often released significant amounts of formaldehyde as a byproduct of the curing process or during the degradation of the polymer. Furthermore, the study noted that the pH of many adhesives was acidic, which contributed to keratoconjunctivitis (inflammation of the cornea and conjunctiva).

Modern manufacturing has shifted toward stabilizing these formulas. At SenseLashes, the focus is on achieving a pH-neutral balance to minimize the caustic potential of the adhesive. However, even with high-purity formulas, the mechanical interaction between vapors and the mucous membranes remains a constant factor.

Logic Summary: Our understanding of fume intensity is based on the vapor pressure of ethyl-cyanoacrylate. Higher temperatures and lower humidity levels can increase the rate of vaporization before the monomer finds a bonding surface, leading to higher concentrations of airborne irritants.

Distinguishing Irritation from Allergic Contact Dermatitis

One of the most common challenges in a professional salon is diagnosing a client's reaction. Is it a localized irritation from fumes, or a systemic immune response?

Physical Irritation (The Fume Response)

Irritation is a localized, non-immunological response to a chemical stimulus. It typically occurs during or immediately after the application.

- Mechanism: Cyanoacrylate vapors seek moisture on the conjunctiva, causing a flash-drying effect on the tear film. This leads to what the Mayo Clinic describes as inflammation, which can mimic the symptoms of blepharitis if hygiene is not maintained.

- Symptoms: Redness in the "whites" of the eyes, stinging, and immediate watering.

Allergic Contact Dermatitis

According to a study published in PubMed (2022), allergic contact dermatitis is caused by a Type IV delayed hypersensitivity to Ethyl Cyanoacrylate.

- Mechanism: The immune system identifies the chemical as a threat and mounts a response. This is not caused by the fumes themselves but by direct or indirect contact with the cured or uncured material.

- Symptoms: Swelling of the eyelids (edema), itching, and redness on the skin of the eyelid rather than the eyeball itself. These symptoms often appear 24 to 72 hours post-treatment.

| Feature | Irritation (Fumes) | Allergic Reaction (Immune) |

|---|---|---|

| Onset | Immediate / During Service | Delayed (24-72 hours) |

| Location | Ocular surface (The eye itself) | Eyelid skin (The "hood") |

| Primary Symptom | Stinging, burning, redness | Itching, swelling, scaling |

| Duration | Usually resolves within 24 hours | Can last several days; requires removal |

Environmental Variables and Vapor Control

The salon environment is a dynamic laboratory. Temperature and humidity do more than just affect your "dry time"; they dictate the behavior of the fumes.

The Humidity Paradox

It is a common misconception that higher humidity makes fumes worse. In reality, adequate humidity (45%–60%) promotes a faster "skin-over" of the adhesive droplet, effectively trapping more monomers within the polymer matrix and reducing the amount that escapes into the air. In very dry environments, the adhesive remains "open" longer, allowing more vapors to dissipate toward the client's eyes.

Ventilation and Airflow Heuristics

In practice, we observe that fume irritation is often most acute in small, enclosed treatment rooms. A frequent mistake is placing an extraction fan too far from the work area or pointing it in a direction that pulls fumes directly across the client’s face.

The Professional "Hand Test": To verify if your airflow is sufficient, place the back of your hand between the client’s eyes and your glue dish. If you can feel a consistent, slight breeze moving away from the client, your ventilation is likely effective. If the air feels stagnant, the vapors will linger in the "breathing zone" of the client.

Modeling Note (Ventilation Efficiency):

- Model Type: Qualitative airflow scenario.

- Assumptions: Room size < 120 sq ft; single extraction unit. | Parameter | Recommended Value | Rationale | | :--- | :--- | :--- | | Fan Distance | < 18 inches from source | Prevents vapor dispersion | | Air Exchange Rate | 6-10 times per hour | Dilutes airborne acrylates | | Glue Dish Placement | Above the client's head level | Vapors are heavier than air | | Humidity | 50% (±5%) | Optimizes curing speed vs. vapor release |

Strategic Product Selection to Reduce Risk

The tools you choose significantly impact the chemical load your client experiences. Professionals must balance the need for speed with the requirement for safety.

Viscosity and Vapor Pressure

There is a direct correlation between the viscosity of an adhesive and its immediate fume release. Higher-viscosity glues (those with a syrup-like consistency) often contain more stabilizers and plasticizers. These additives can lower the vapor pressure, meaning fewer molecules escape into the air at room temperature compared to very thin, "instant-dry" glues.

For clients with known sensitivities or dry eye syndrome—a condition the WebMD guide on Dry Eyes notes can be exacerbated by chemical irritants—switching to a medium-viscosity adhesive can provide a more comfortable experience without sacrificing retention.

Fiber Choice and Bonding Surface

The weight and surface area of the extension also play a role. Heavier extensions require more adhesive, which increases the total volume of cyanoacrylate used. By utilizing 0.10MM Ellipse Flat Classic Eyelash Extensions, artists can achieve a bold look with significantly less weight and a larger bonding area. This "flat" base allows for a more efficient wrap around the natural lash, often requiring less adhesive to achieve a secure bond compared to traditional round fibers.

For mega-volume sets, using ultra-fine fibers like the 0.05MM Cashmere Premium Mega Volume Eyelash Extensions ensures that the fan remains lightweight. This reduces the mechanical stress on the natural lash, which PubMed (2024) identifies as a contributing factor to long-term ocular disorders.

Clinical Insights: Protecting the Ocular Surface

Beyond the adhesive, the physical protection of the eye during application is paramount. The American Academy of Ophthalmology (AAO) emphasizes that the risks of extensions include not just chemical irritation, but also mechanical trauma and infection.

Preventing Chemical Burns

A chemical burn occurs when liquid adhesive or primer makes direct contact with the eye. This is often the result of poor isolation or the "creeping" of liquid products. Case reports in PMC (9870835) highlight that corneal abrasions can occur during the removal process if liquid removers run into the eye. This is why we transition professionals toward non-drip cream removers.

The Importance of the Tear Film

Recent research in PMC (11173262) suggests that eyelash extensions can alter tear film stability. The presence of cyanoacrylate fumes can temporarily disrupt the lipid layer of the tear film, leading to rapid evaporation and the sensation of dry eyes.

To mitigate this, many experienced technicians use a nano-mister at the end of the service. The fine mist provides the controlled moisture needed to complete the polymerization of the surface layer of the adhesive, "sealing" the fumes and restoring a degree of moisture to the ocular environment.

Salon Sanitation and SOPs

To build a high-trust salon, your sanitation protocols must be transparent and rigorous. Following CDC guidelines on conjunctivitis prevention is the baseline.

Standard Operating Procedure (SOP) for Sensitivity Management:

- Hydration Check: Ask clients to hydrate well before their appointment. A thicker tear film provides a better natural barrier against vapors.

- The Tape Test: Use medical-grade foam tape to ensure the eyes are fully closed. Even a microscopic gap allows fumes to enter the eye.

- Adhesive Management: Use a fresh drop of adhesive every 15–20 minutes. As the glue sits on your stone, it begins to polymerize and release more fumes.

- Aftercare Education: Educate clients that "water is not enough." Use a dedicated lash shampoo to prevent the buildup of oils and bacteria that lead to blepharitis.

For beginners or those looking to standardize their kit, starting with 0.10MM Premium Classic Eyelash Extensions in mixed trays allows for versatility while you master the nuances of adhesive control and environmental management.

Managing Compliance and Professional Longevity

As the industry matures, regulatory bodies like Health Canada are increasing scrutiny on cyanoacrylate-based products. Ensuring your supplies are compliant with labeling and chemical safety standards protects your business from liability and your clients from substandard ingredients.

Understanding the "why" behind fume irritation transforms you from a service provider into a technical expert. By controlling the environment, selecting high-purity products like 0.15MM Premium Classic Eyelash Extensions, and adhering to medical-grade hygiene standards, you ensure that the beauty of the lash set is never compromised by the safety of the application.

For further reading on optimizing your application technique, explore our guides on How Fiber Surface Texture Impacts Adhesive Bond Strength and Why Professional Lashes Lose Curl.

YMYL Disclaimer: This article is for informational purposes only and does not constitute professional medical advice, diagnosis, or treatment. Always seek the advice of a physician or other qualified health provider with any questions regarding a medical condition. Eyelash extensions should only be applied by trained and certified professionals.

References

- Centers for Disease Control and Prevention (CDC) - Conjunctivitis Prevention

- American Academy of Ophthalmology (AAO) - Eyelash Extension Safety

- Mayo Clinic - Blepharitis Symptoms and Causes

- Amano et al. (2012) - Formaldehyde and pH in Eyelash Glue

- Health Canada - Compliance Report on Cyanoacrylate Adhesives (2023-2024)

- PubMed - Allergic Contact Dermatitis from Ethyl Cyanoacrylate (2022)

- PMC - Ocular Surface Changes and Eyelash Extensions